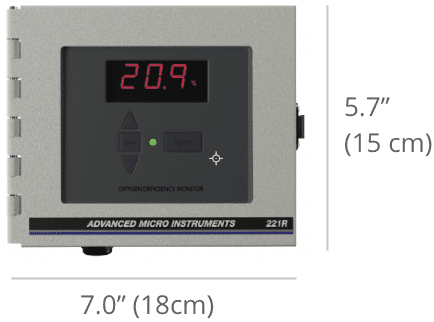

Oxygen Deficiency Monitor

Model 221R

Price: $1,870.00

SHIPS NEXT BUSINESS DAY

up to 10 units

Pricing shown is for North America only. For other regions, contact your local distributor or AMI for pricing.

Select Your Configuration

DESIGNED FOR SAFETY

The AMI MODEL 221R is the gold standard for oxygen deficiency & confined space oxygen monitoring. It is used by the thousands in US Government Laboratories, Space Agencies, Universities and a broad range of industries to ensure the safety of personnel. The MODEL 221R provides an incredibly accurate and stable reading over a wide temperature range (0-130°F) and is not affected by changes in barometric pressure. This analyzer is virtually maintenance-free with its unique oxygen sensor delivering a 10-year life expectancy.

Note that the MODEL 221R should not be used in areas where Flammable Gases may be present.

Features & Benefits

Why Choose AMI?

The AMI Model 221R offers the most reliable safety oxygen deficiency monitor to protect your staff. How can you be sure? Keep reading to learn about the AMI difference.

Advanced Micro Instruments 221R

Competitor #1

Competitor #2

Zirconium Oxide based sensors are the best option for Oxygen Deficiency Monitors and commonly used by most major manufacturers including AMI. They offer up to a 10-year service life as well as being incredibly accurate, not affected by sudden swings or drifts in barometric pressure, and require minimal maintenance over the life of the sensor.

Having only two alarms limits a unit to only measuring for low oxygen levels. The additional of a third alarm allows the 221R to monitor for oxygen-enriched environments, which is recognized by OSHA as a health risk.

Oxygen Enrichment Alarm

The AMI DifferenceOxygen-enriched environments are recognized by OSHA as a health risk. Companies that want to protect employees across the entire spectrum for oxygen safety, from low to high levels, should make this a requirement in their purchase decision. The 221R contains a dedicated oxygen enrichment alarm that triggers at a preset threshold of 23.5%.

Default Alarms Settings

The AMI DifferenceAlarm one: 19.5%,

Alarm two: 20.0%, and

Alarm three: 23.5%

Alarm one: 19.5% and

Alarm two: 18.0%

Alarm one: 19.0%,

Alarm two: 17.0%, and

Alarm three: 15.0%

AMI's 221R is designed and configured to power-up and be ready to monitor 'straight out of the box'. It is preset with OSHA's critical thresholds of 19.5% for 'deficient oxygen levels' and 23.5% for 'oxygen-enriched environments'. It also is the only unit that contains a preset warning alarm at 20% to give staff a 'safety buffer' and more time to exit before an environment becomes oxygen-deficient. Other units require set-point adjustments, which can add complexity to the installation and introduce the potential for errors - all of which can have a critical impact on safety.

Adjustable Alarm Set-Points

The AMI DifferenceThe main purpose of oxygen monitoring is to keep an environment safe for staff with thresholds specified by OSHA. That means monitoring for oxygen at preset thresholds of 19.5% and 23.5% oxygen. If these setpoints are adjustable, it introduces a major RISK for both safety and compliance.

4-20 mA Outputs

The AMI DifferenceAll Major Oxygen Deficiency Monitoring units include these output signals.

Oxygen deficiency monitors are commonly installed and used within industrial and commercial environments. AMI's metal enclosure will provide superior protection to physical abuse that can be common in harsh environments.

Access to Controls

The AMI DifferenceEasy access latched, hinged,

lockable protective door

Screw on cover

No protection,

exposed controls

Easy access to the control buttons of an oxygen deficiency monitor is important for calibrating the product. It is also important to protect the controls from damage or accidental tampering. Some solutions have a screw on cover that requires a screw driver to remove. Others provide zero protection for the controls. AMI's 221R has a hinged metal cover with viewing window. It will protect the analyzer controls while still allowing quick access for a technician. It can also be locked, if desired, to protect against tampering.

Washdown-Ready

The AMI DifferenceSome facilities must perform washdowns for sanitary compliance. So It is important they select an Oxygen Deficiency Monitor designated as 'Washdown-Ready'. AMI's 221R is engineered for use in a washdown environment. Whereas other deficiency monitors will fail due to sensor or electronics damage from water ingress.

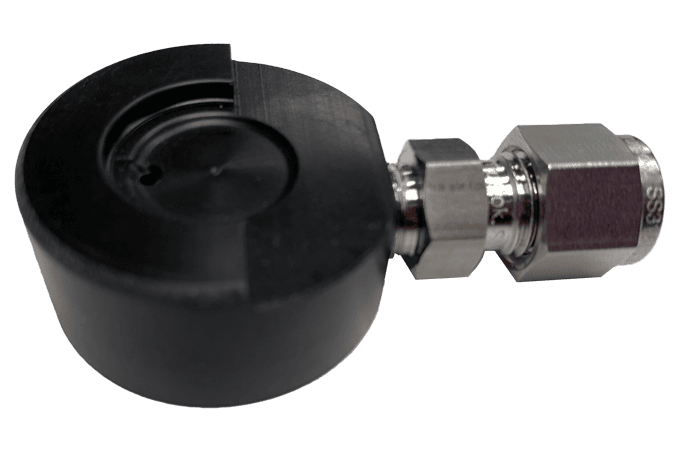

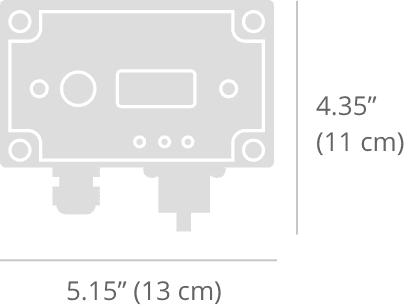

Remote Sensing Capability

The AMI DifferenceMost manufacturers offer remote monitoring capability through the purchase and installation of a probe or display unit that becomes wired to the main control unit. But monitoring ranges among manufacturers can differ significantly. Understand a greater range offers greater flexibility, and this is especially true for companies that are constrained by difficult floor plans. The remote probe of the 221R can be installed up to 300 ft away from the main console, offering customers the furthest range in the industry.

Built-in Battery Back-Up

The AMI DifferenceOxygen safety monitoring must operate 24/7. But facilities must always be ready to contend with an unexpected including loss of power. If an Oxygen Deficiency Monitor has no emergency power, staff is at immediate risk in the surrounding areas until power is restored. The 221R includes a built-in battery back-up for this type of situation and ensures no disruptions to your monitoring for safe oxygen levels.

Power Loss Alarm

The AMI DifferenceIn addition to a battery back-up, it is important to know if power is ever lost to the Oxygen Deficiency Monitor. The 221R contains an audible alarm, and it will trigger if the monitor loses power and the back-up batteries are nearing charge depletion.

The price point of the 221R is extremely compelling when considering all its unique features and advantages not seen on other competitive units.

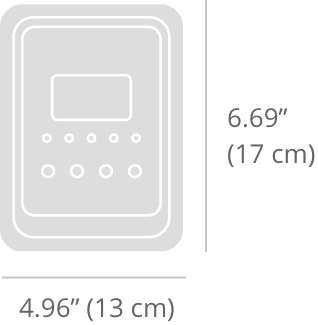

Technical Specifications

| WEIGHT | MOUNTING | GAS CONNECTIONS | Digital Display |

| 4.0 lbs (1.8 kg) | Wall mount | Diffusion screen. No pump, sample tubing or fittings required | 3-digit LCD (reads full scale from 0.0% to 25.0%) |

| POWER | OUTPUTS |

| 100 –240 VAC <11 Watts. Battery back-up provides 1 hour of power | 4 – 20 mA isolated output signal Bi-directional RS485 communication |

| Measurement Range | AMBIENT OPERATIONAL TEMPERATURE range | Method of Measurement |

| 0 –25.0% | +14°F to +122°F (-10°C to +50°C) | Zirconium Oxide Sensor (10-year life expectancy) |

| Minimum detection limit | 90% UPSCALE RESPONSE TIMES FOR SPECIFIC RANGES | REPEATABILITY | Diurnal Temperature Specification | APPROVALS |

| 0.05% of Oxygen | <12 sec for 0.0% – 25.0% | ±0.1% of range or ±0.1% of oxygen whichever is greater | <±1% of scale over temperature range | UL 61010-1 for Safety Electrical Equipment CE Marked, Designed to Meet IP65 |

| TAMPER RESISTANT PRESET ALARMS | OSHA Preset Standard Alarms

Additional Preset Alarm

|

| WASH DOWN READY | Designed to withstand direct water spray |

| SAFETY FEATURES |

|

| ACCESSORIES |

|

| COMMAND CENTER SOFTWARE | Included Software, which provides access to advanced functions:

|

Video Library

Available Accessories

Model 221R Downloads

- Data Sheetmodel-221r-data-sheet.pdf (3.2 MB)

- Operator Manualmodel-221r-operator-manual.pdf (711 KB)

- More Downloads

Industry Applications