Why Measure Moisture in Natural Gas?

Trace moisture analysis is a critical measurement in the Natural Gas Industry. Water content in natural gas increases both the cost of transportation and compression and does nothing to increase the heating value of the gas. Even in small trace amounts, water can combine with O2, CO2 and H2S to form a corrosive mixture that can cause damage to a pipeline, even to the point of rupture. For these reasons, natural gas is typically ‘dried’ or dehydrated to remove as much water as possible before its introduction into the pipeline network.

Moisture measurements are performed before and after processing and storage and during transportation to ensure that the water content of the gas falls within acceptable limits. These levels are set by tariff and govern the custody transfer between the current owner and future owner of the gas as it is being moved through the pipeline. Within the U.S., the established moisture limit for interstate transfer is 7 lbs/mmscf.

Trace Moisture Measurement Technologies

Several technologies are available to measure the moisture content in natural gas. There are advantages and disadvantages associated with each with some more popular with pipeline operators than others.

TDL (Tunable Diode Laser) | This technology provides a non-contact method of continuous moisture measurements and is based on the Beer-Lambert Law. The Law states that when a laser is passed through a sample gas, its light energy will be absorbed by the water molecules of the gas in its pathway at specific wavelengths. This absorbed energy can be measured and used to calculate the amount of water content in the sample gas. | Pros:

| Cons:

|

Impedance | Analyzers with this technology typically utilize aluminum-oxide sensors. The construction of these sensors involves depositing a thin layer of porous gold over a small matrix layer of aluminum oxide with parallel pores, all on top of an aluminum base. When water molecules in the sample gas pass through the sensor and collect in these pores, an additive capacitance reaction takes place that produces a low voltage alternating current. This current is used to calculate the amount of water in the sample gas. | Pros:

| Cons:

|

Quartz Microbalance | This type of sensor technology uses a quartz substrate that is coated with a hygroscopic polymer film. Once voltage is applied, the entire structure oscillates. When moisture comes in contact with the film, it gets absorbed and increases the mass of the entire quartz structure. This increased mass changes the frequency of the oscillation and is proportional to the partial pressure of the water level in the sample gas. | Pros:

| Cons:

|

Fabry-Perot | This approach relies on passing a light beam through a sensor and measuring the change in wavelength. The sensor head is coated with a substrate, consisting of materials having high and low refractive indices (SiO2 and ZrO2 are typically used). The substrate has small pores with a size specific to water molecules. If water molecules are present in the gas sample, they will be absorbed by the substrate and cause the refractive index of the light beam to change as it passes through the sensor. This change will also cause a change in the wavelength, which is proportional to the amount of water molecules measured on the sensor. The moisture measurement is finally calculated from a reference that plots dew temperature against wavelength shift. | Pros:

| Cons:

|

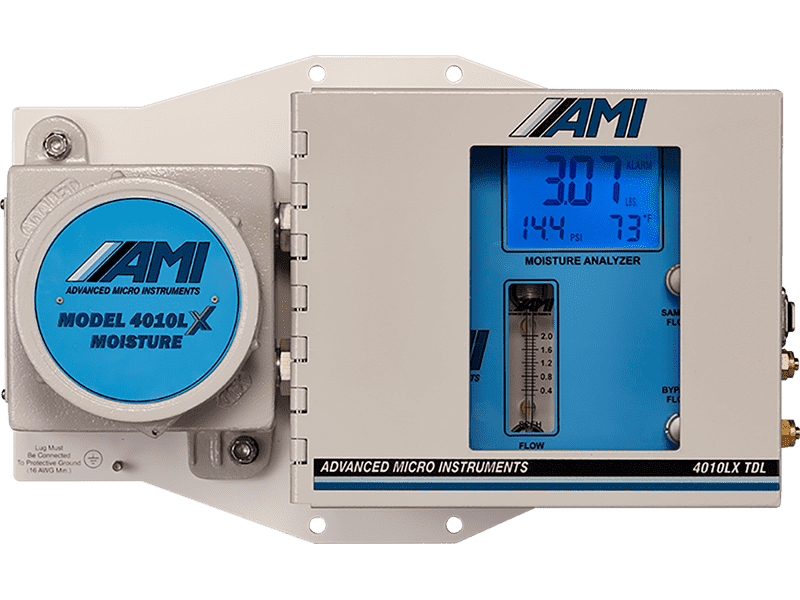

Latest TDL Analyzer Designs

New TDL Moisture Analyzers have been introduced to the market in recent years. Based on the Beer-Lambert Law, manufacturers can control 2 things in their TDL design to further optimize the measurement accuracy and reliability of the Analyzer.

Design Change #1

First, the newer TDL Absorption spectrometers feature a longer optical laser path for maximum absorption. This is achieved by utilizing a multi-pass absorption cell in the design of the sample gas chamber. Compared to a single-pass design, the multi-pass laser travels a distance that is many times longer. This clever approach achieves a longer laser path without having to increase the overall size of the Analyzer.

Design Change #2

Second, manufacturers have begun releasing new TDL Moisture Analyzers that measure at a specific wavelength. Since different wavelengths provide different levels of accuracy and precision, companies have conducted R&D to target which ones are the best to use. In fact, some manufacturers have put certain wavelengths under patent protection for use only with their Analyzers.

Important Features to Consider

Measuring trace moisture in the Natural Gas Industry comes with its own set of unique challenges. Therefore, users should be cognizant if an Analyzer can handle or accommodate the following requirements:

Low Power Consumption

There are times when pipeline operators need to perform trace moisture measurements in a remote field location where no supply of electricity is available. In these instances, solar power can be a viable solution only if the power requirements of the Analyzer remain below a certain level for full operation.

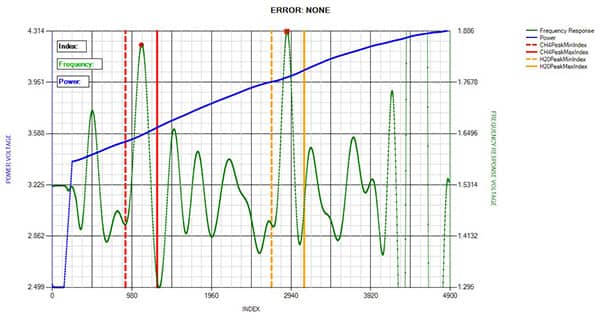

Absorption Peak Realignment

Over time, the signature peaks gradually shift on the x-axis of the measurement waveform of a laser-based Moisture Analyzer. When this happens, the accuracy and reliability of the moisture measurement can be impacted. To realign the peaks, some manufacturers require users to complete a complicated manual process in the field or for customers to ship their analyzers back and pay a substantial fee. However, new solutions now exist which allow customers to use software on a laptop, while connected to the Analyzer, to complete the process. It is not only easier, but it reduces the Analyzer’s downtime from performing trace moisture measurements.