What is Wastewater Treatment?

Wastewater treatment is the process of removing contaminates from water to a level which it can be safely released into the environment or reused for industrial purposes. There are a multitude of water treatment technologies commonly utilized with varying levels of contaminant removal as well as varying levels of cost associated with them. The location where the treated wastewater is being released or reused will dictate what levels of residual contaminates are acceptable.

Wastewater treatment is commonly performed at facilities operated by local or regional municipalities. There are over 14,000 municipal wastewater treatment facilities in the United States that employ a combination of chemical, physical and biological processes to treat the sewage. There are also numerous wastewater treatment operations within industrial settings to manage the water used in industrial plants.

What are the Steps of Wastewater Treatment?

Almost all wastewater treatment facilities have some form of the following processes:

Primary Treatment – the sewage from residential, commercial and industrial users reaches a wastewater treatment plant through either a network of sewer pipes or trucking to the facility. It enters the plant at the primary treatment process, which screens out larger solids and grit in preparation for further treatment. At this step, there are also clarifiers that allow heavier solids to sink and lighter debris to float and be removed from the waste stream.

Secondary and Tertiary Treatment – the fluid stream from primary treatment clarification is treated with aerobically grown microorganisms, called bugs, that consume the phosphorous, nitrogen and other organic impurities in the aqueous stream. The bugs in the wastewater require significant amounts of oxygen, which is introduced through aeration using blowers or compressors.

Disinfection – this is the final step for the water before it is released into the environment. In this step, infectious pathogens must be neutralized to render the effluent safe. The level of disinfection will vary, depending on how the water will be used.

Biosolids Treatment – The biosolids, or sludge, that comes out of the primary treatment and secondary treatment processes are treated through digestion. The anaerobic or aerobic digestors utilized bacteria to break down the solids, reduce the odors and rid the sludge of harmful organisms. The sludge is also dried to remove excess water.

What is a Wastewater Resource Recovery Facility or WRRF?

A Water Resource Recovery Facility or WRRF is a newer term to refer to wastewater treatment plants. The new name reflects the change in focus of traditional wastewater treatment facilities from solely treating wastewater to also actively working to recover the resources, nutrients and energy that are present in municipal wastewater.

Through the treatment process of sewage at a WRRF, one of the common energy recovery opportunities is to utilize the methane-rich gas that is produced in an anaerobic digestor. The digestor gas, or biogas, can be cleaned and converted into fuel for boilers or used to produce electricity for the WRRF. The biogas can also be injected into commercial natural gas pipelines or used to power natural gas vehicles.

The treated biosolids from the WRRF are rich in nitrogen and phosphorous. When dewatered and treated appropriately, the biosolid sludge can be used as a fertilizer in agriculture. Finally, the clean water coming from a WRRF can supplement potable water in a community or serve as a source of non-potable water for irrigation.

How is Biogas Produced from Wastewater?

The solid biological waste, referred to as biosolids or sludge, is a byproduct of the treated wastewater in the sewage treatment process. Beyond the obvious human waste, this sludge can include other organic material such as food waste, fats, oils, grease, pharmaceuticals or anything else that can find its way into sewage. This sludge must be treated to remove harmful pathogens and contaminates before it can be disposed of.

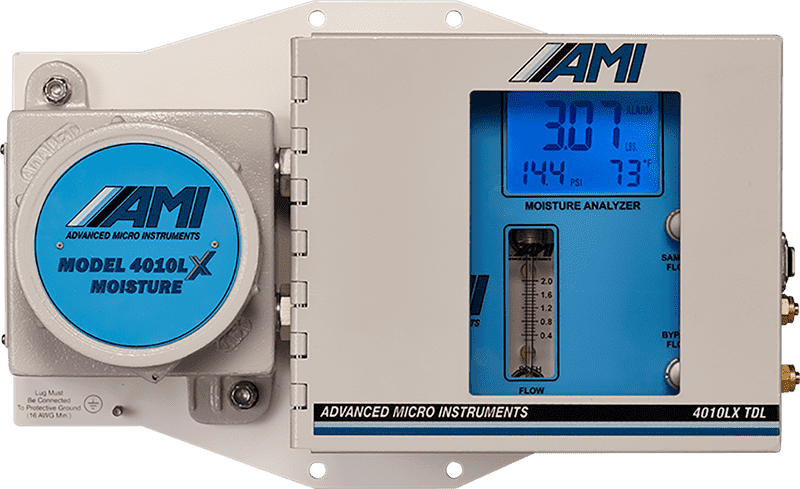

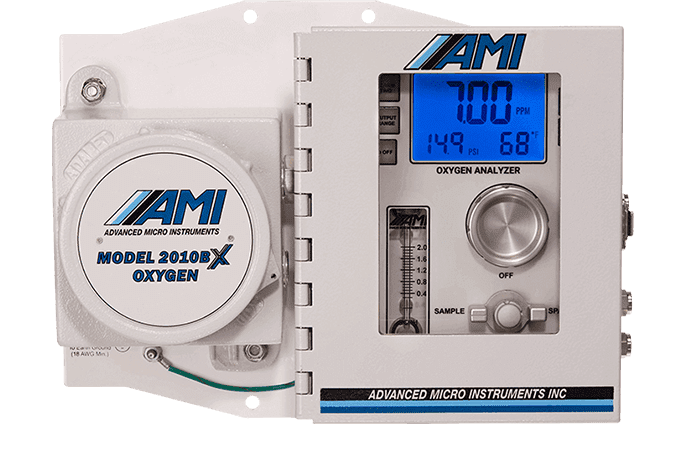

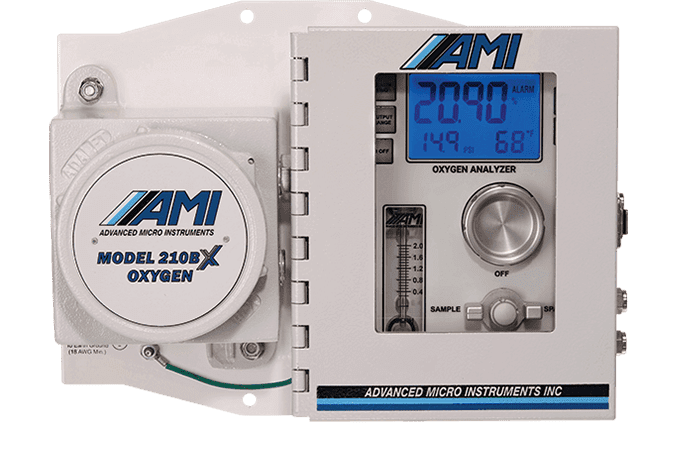

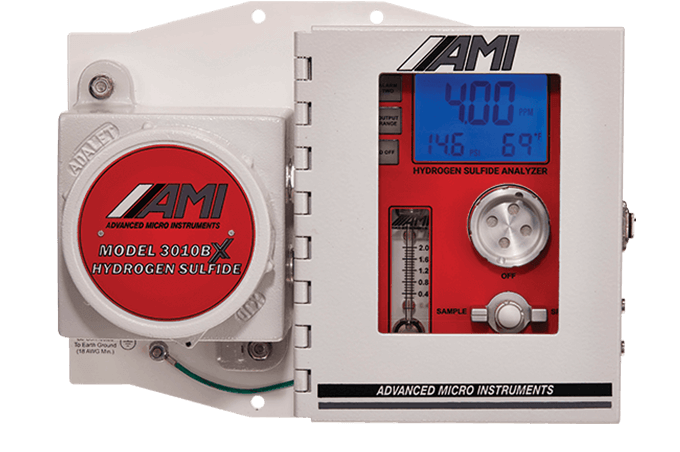

Anaerobic digestion is one common method for neutralizing the harmful pathogens and employed at over 1,200 of the 14,000 wastewater treatment plans in the United States. One of the byproducts of this process is methane. Some facilities will flare the methane on site, but it is becoming much more common to capture the gas for beneficial reuse, such as for running the treatment plant or upgrading the methane to biogas so that it can be injected into municipal gas pipelines. When upgrading of the digestor-produced gas for use as biogas, the operator must take care to monitor oxygen, hydrogen sulfide, and moisture levels in the gas. Often, they will use AMI’s 2010BX O2 analyzers, 3010BX H2S analyzers or 4010 moisture analyzers to control the upgrading process.

What Causes H2S in Wastewater Treatment?

Having Hydrogen Sulfide gas within wastewater treatment systems is a well-known issue that plant operators must always be concerned about. When H2S is present, it can be the source of several problems, including corrosion of steel and concrete as well as causing the classic “rotten egg” sewage smell that can be offensive to surrounding communities. H2S gas in relatively low concentrations can also be hazardous to those working in the confined spaces of a wastewater treatment plant and collection systems.

Hydrogen sulfide gas is formed through biological, chemical, and physical processes within sewer systems. It starts with the conversion of naturally occurring sulfates into ionic sulfides. Next, the sulfides dissolve in the water to form H2S, which then enters a gas form through turbulence in the waste stream. Bacteria in the sewers will then convert the H2S into corrosive sulfuric acid, resulting in damage to the treatment infrastructure.

What Levels of H2S Must Be Measured?

Hydrogen sulfide can have very detrimental effects at very low concentrations. The characteristic rotten egg smells of H2S can be detected at levels as low as 3 ppm. In the range of 10 to 50 ppm, hydrogen sulfide can begin to have physiological impact on humans such as headaches, nausea and irritation of the throat and eyes. Once levels exceed 100 ppm, the human nose will become paralyzed to the smell of the gas, therefore eliminating the ability to simply detect the hazard by odor.

The detection of very low level of hydrogens sulfide can be readily achieved utilizing electrochemical gas analyzers. AMI’s line of portable and fixed H2S analyzers is designed for use in these hazardous environments and can detect H2S levels as low as 0.1 ppm.