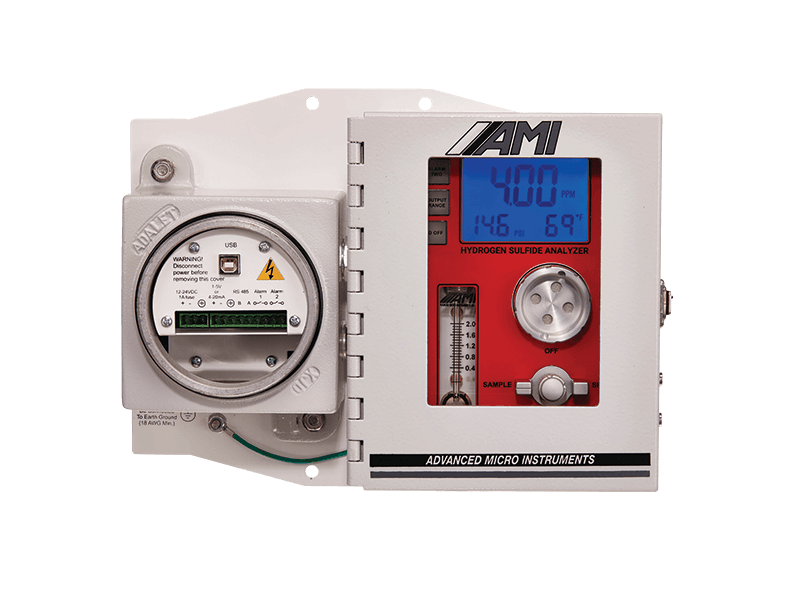

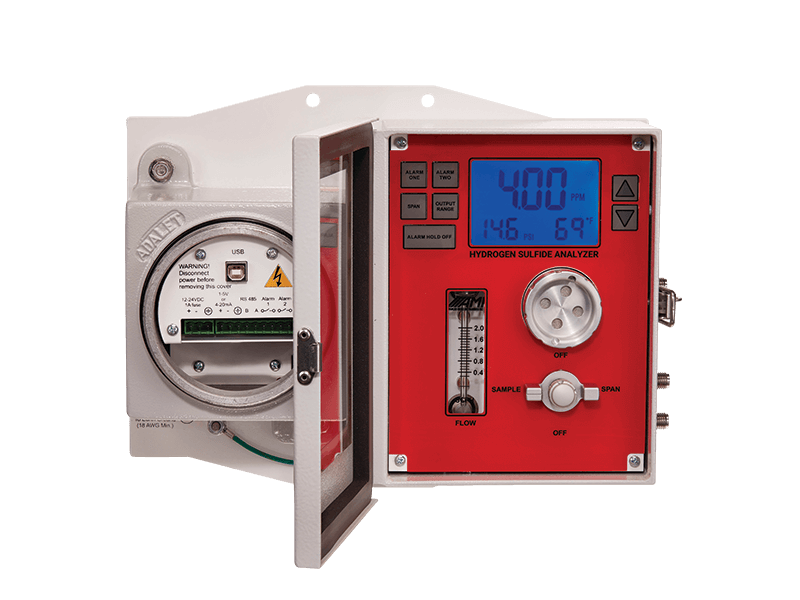

Model 3010BX

DEPENDABLE H2S MEASUREMENTS MADE INCREDIBLY EASY

The MODEL 3010BX is AMI’s neXt generation Trace H2S Analyzer. Its patented technologies and superior design make the Analyzer the top pick among engineers and measurement technicians seeking reliable and accurate H2S measurements under harsh conditions.

Technical Specifications

| WEIGHT | MOUNTING | GAS CONNECTIONS | WETTED PARTS |

| 16.0 lbs (7.26 kg) | Wall Mount or 2.0” Pipe | ¼” 316 S.S. compression fittings | 316 S.S. fittings, electro-less nickel-plated cell block, gold-plated contacts, acrylic flow meter & O-rings (Viton, kalrez, and Buna-N) |

| POWER | |

| DC | AC |

| 10 – 24 VDC, 150 mA max (non-heated) 10 – 24 VDC, 2.2 Amps max (heated) | 100 – 240 VAC, 150 mA max (non-heated) 100 – 240 VAC, 550 mA max (heated) |

| OUTPUT RANGES (USER SELECTABLE) | AMBIENT OPERATIONAL TEMPERATURE | |||

| Standard Ranges | Optional High Range Sensor | NON-HEATED | Heated | HEATED WITH EXTREME WEATHER ENCLOSURE |

| 0 – 10 ppm 0 – 50 ppm 0 – 100 ppm 0 – 200 ppm0 – 100 ppm 0 – 500 ppm 0 – 1000 ppm 0 – 2000 ppm | 25°F to 115°F (–3.9°C to 46°C) | –20°F to 115°F (–29°C to 46°C) | –40°F to 115°F (–40°C to 46°C) | |

| FLOW RATE (RECOMMENDED) | INLET GAS PRESSURE | Operational Altitude | |

| DC | AC | ||

| 1.0 to 1.5 SCFH (0.5 – 0.75 Lpm) | 0.5 − 150 psig (0.03 − 10.3 bar) | ≤ 5,500 m (18,000 ft) | ≤ 2,500 m (8,200 ft) |

| Low Range Sensor | High Range Sensor | 90% UPSCALE RESPONSE TIMES @ 1.5 SCFH (0.75 Lpm) FOR SPECIFIC RANGES | REPEATABILITY | ACCURACY | |

| Max Range 0 –200 ppm | Max Range 0 –2000 ppm | <120 sec for 0 – 100 ppm | <120 sec for 0 – 2000 ppm | ±1% of range or ±0.2 ppm of H2S, whichever is greater | ±1.5% of full scale range at constant conditions |

| APPROVALS | |||||

| Class I, Division 1, Groups B, C & D, T4 Class I Zone 0/1, AEx ia/db IIB+H2 T4 Ga/Gb | IECEX: Ex ia IIB+H2 T4 Ga/Ex db IIB+H2 T4 Gb UKCA/PESO: Ex ia/db IIB+H2 T4 Ga/Gb -32°C ≤ Tamb ≤ +46°C | ATEX: II 1/2 G Ex ia/db IIB+H2T4 Ga/Gb Ingressed Protection: IP65 | |||

| RESPONSE TO OTHER GASES IN THE SAMPLE GAS (GIVEN THAT 100 PPM OF THE LISTED GAS IS PRESENT) | ||||

| Methyl Mercaptan (40 ppm) | Carbon monoxide (4 ppm) | Hydrogen (1 ppm) | Sulfur dioxide (18 ppm) | Note: For complete list, contact AMI |

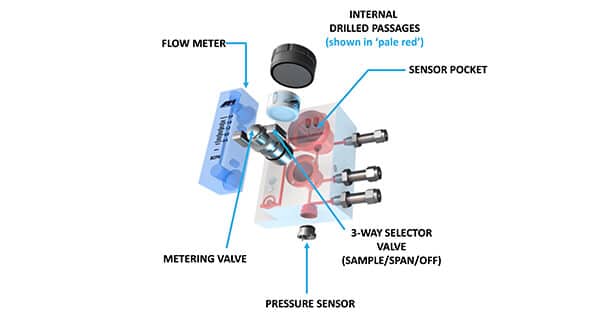

| ELIMINATOR CELL BLOCK | Contains a Complete Sample System with all components, including the flow meter, metering valve, pressure sensor and 3-way Selection (Sample/Span/Off) Valve, fully integrated |

| ALARMS | 2 fully adjustable concentration alarms with configurable Alarm logic and Relay Contacts, featuring:

|

| INTERNAL PRESSURE SENSOR | Measures gas inlet pressure from 0 – 150 psig |

| ANALOG OUTPUTS | 1 − 5 VDC and 4 − 20mA isolated output signals and Modbus bi-directional RS485 communication |

| COMMAND CENTER | Software that works across AMI’s Analyzers and gives users access to advanced functions:

|

| ACCESSORIES |

|

Features & Benefits

ELIMINATOR CELL BLOCK For A Leak-Free Design

The patented ELIMINATOR CELL BLOCK provides a unique, compact sample system approach and a flow-efficient sensor pocket, machined into a solid metallic block. Precision cross-drilled intersecting gas passages eliminate the need for long lengths of tubing and leak- prone compression fittings. Additionally, a uniquely engineered 3-way selector valve (Sample/Span/Off), metering valve, pressure sensor and flow meter are all integrated into theELIMINATOR CELL BLOCK. It also provides the user with direct front panel access for installing and replacing sensors without the need for disassembly or tools.

Designed for the user

Intuitive controls, compact size, rugged design make the MODEL 3010BX simple to install and ideally suited for either indoor or outdoor use. The Analyzer’s low power requirements allow even the heated configuration to be powered in remote locations with just a solar panel. High performance and reliability combined with a virtually maintenance free operation makes the MODEL 3010BX a simple, low cost, long term solution for measuring H2S.

FULL SUITE OF STANDARD FEATURES

AMI’s MODEL 3010BX Trace H2S Analyzer comes loaded with a full suite of advanced features without the typical ‘up charges’. The standard features include: 4-user selectable analog output ranges, large backlit LCD, dual independent alarm relay contacts, comprehensive alarm logic (fail safe or non-fail safe, latching or non-latching and independent alarm delays), alarm bypass, and 3 levels of security settings. Automatic data logging provides detailed time-stamped records of H2S measurement, gas pressure, temperature, supply voltage and power brown-out history. All these features can be accessed through AMI’s powerful COMMAND CENTER software, which works universally across all AMI analyzers

Available Accessories

Model 3010BX Downloads

- Data Sheetmodel-3010bx-data-sheet.pdf (2.1 MB)

- Operator Manualmodel-3010bx-operator-manual.pdf (7.5 MB)

- Natural Gas Product Portfolionatural-gas-product-portfolio.pdf (7.3 MB)

- Quick Start Guidemodel-3010bx-quick-start-guide.pdf (1.5 MB)

- More Downloads

Industry Applications