What is Biogas?

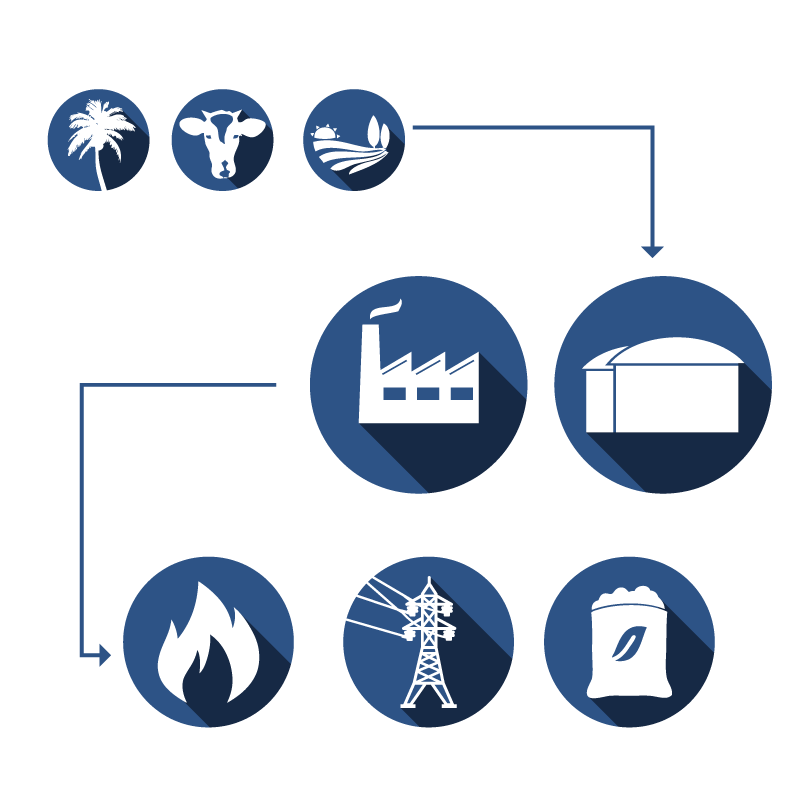

Biogas is a mixture of methane, CO2 and small amounts of other gasses produced during the breakdown of waste organic materials. The organic matter is broken down by bacteria in an oxygen free environment through a process called anaerobic digestion. The exact composition of the biogas will vary based on the types of organic feedstock being digested. The organic materials can include animal and plant waste, sewage treatment biosolids, food waste and materials in municipal landfills. The biogas that is captured can be used in a variety of valuable ways including local heating and power generation, as fuel for natural gas vehicles, or sold to natural gas utilities and injected into their pipelines in the form of biomethane. Depending on the end use of the biogas it must be conditioned or upgraded to different levels of purity to remove contaminates such as hydrogen sulfide, oxygen and moisture.

How is Biogas produced?

Biogas is produced through the anaerobic digestion of waste organic materials. Anaerobic digestion is a series of biological processes in which microorganisms break down organic material in the absence of oxygen within a bioreactor or digester or within a municipal landfill. As the organic materials break down, they produce a gas mixture of methane and CO2 as well as small amounts other gasses like hydrogen sulfide.

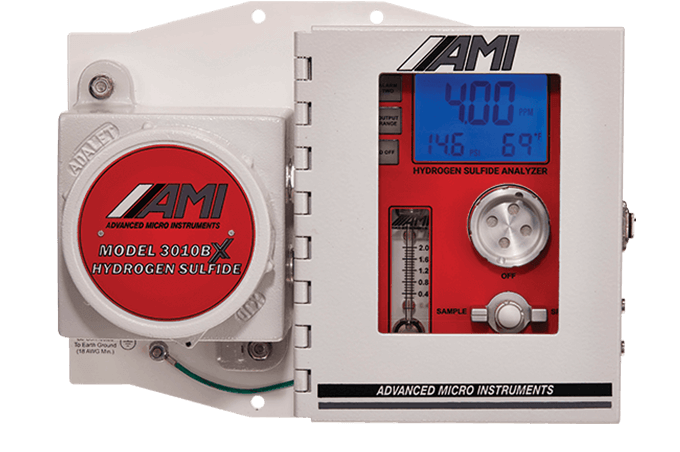

The biogas is captured and depending on its final intended use it may require further processing to remove impurities. When the biogas is used to power industrial engines or boilers it can typically have higher levels of traces gasses like hydrogen sulfide. When the biogas is being be injected into natural gas pipelines it must be upgraded to biomethane or renewable natural gas (RNG) which has a much higher purity level. Biomethane will often be required to have H2S level below 4 ppm as well as have strict controls on CO2, Oxygen and moisture levels. AMI’s Oxygen, H2S and moisture analyzers are utilized within the biogas production process to monitor the trace levels of these gas during the biogas production process.

Why Produce Biogas?

Production of biogas yields multiple economic and environmental benefits. The value chain of biogas production is often anchored with a large producer of waste organic materials such as a diary, a sewage treatment plant, an agricultural operation, or a food producer. Landfills are also a major source of biogas produced by the buried refuse. These operations often face government mandates to limit the production of greenhouse gasses from their waste materials as well as a requirement to divert their waste materials away from landfills. By utilizing anaerobic digestion all these types of operations can convert their waste to digestate and biogas. The digestate is the solid waste materials after anaerobic digestion that can be utilized as a soil conditioner for agriculture thus eliminating landfill disposal costs. The biogas produced can be flared, or burned, but it is often used on site as an energy source or sold as fuel.

Where is biogas produced?

Biogas is a common operation in a wide range of settings including food production facilities, farms, solid waste processing facilities and municipal wastewater treatment plants. All of these facilities deal with a wide range of waste organic materials that must be disposed of. These locations, except for landfills, will commonly utilized anaerobic digesters which will process the waste organic materials, called feedstock. Common feedstocks will include animal manure, food waste, agricultural waste, waste fats and oils, and municipal sewage sludge or biosolids. The biogas produced during the anaerobic digestion process is captured and either utilized at the facility for heating power generation or it can be sold as natural gas or used for powering vehicles. While landfills do not have digestors, they will also have systems capture the off-gassing from the buried solid waste materials that have been deposited at the site.

What is an Anaerobic Digester?

Anaerobic digesters are airtight (oxygen free) structures in which organic materials go through the anaerobic digestion process. They are an integral part of the process in the production of biogas. Anaerobic digesters have been in use since the mid-1800’s for sewage treatment and to production of methane for various uses. There are several types of digesters including large airtight cement tanks like those found at wastewater treatment plants or simple covered lagoons which are typically utilized at a dairy to handle manure digestion.

The process by which anaerobic digestion takes place is basically the same regardless of the type of digester. The organic materials put into the digester are broken down by naturally occurring microorganisms to produce the biogas and digestate. Biogas can be used for a variety of beneficial applications such as heating or generating electricity. The digestate is the left over solid and liquid materials. The digestate can have valuable nutrients such as nitrogen, phosphorous and potassium. Digestate is often further processed for use as fertilizer, compost and animal bedding.

What is Biogas Upgrading?

When the biogas is intended for injection into natural gas pipelines or use as vehicle fuel it must be upgraded to meet the gas quality standards of these markets and applications. Biogas produced by an anaerobic digestor or captured in a landfill will typically contain 40-60% methane (CH4) and up to 40% carbon dioxide (CO2). It is also commonly saturated with water vapor and will include varying amounts of hydrogen sulfide (H2S), nitrogen (N2), oxygen (O2) and siloxanes. The goal of upgrading the gas is to get it to 99% CH4 with only trace amounts of other constituents. The final requirements for the gas matrix are dictated by the commercial buyer of the biogas. Proper operation of the biogas upgrading systems as well as consistent operation of the anaerobic digestors is critical to a successful biogas operation.

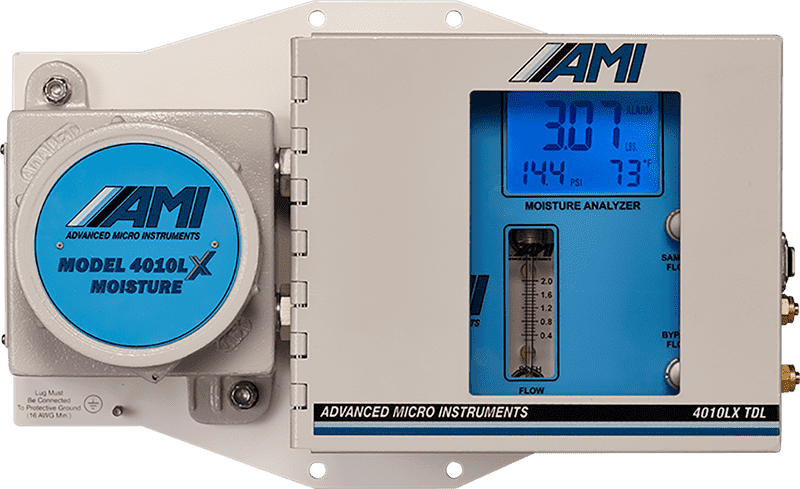

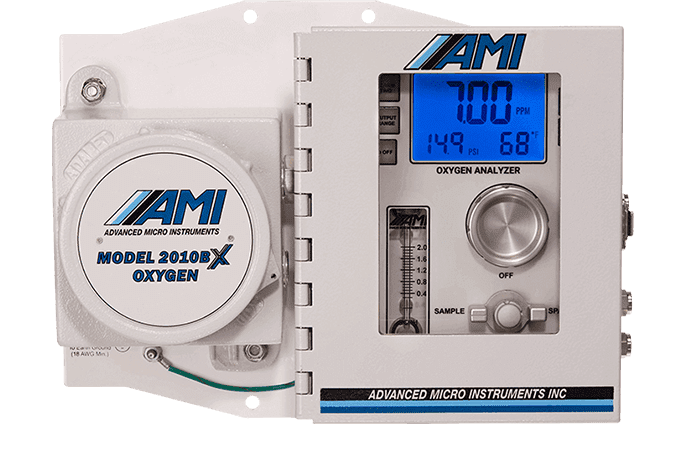

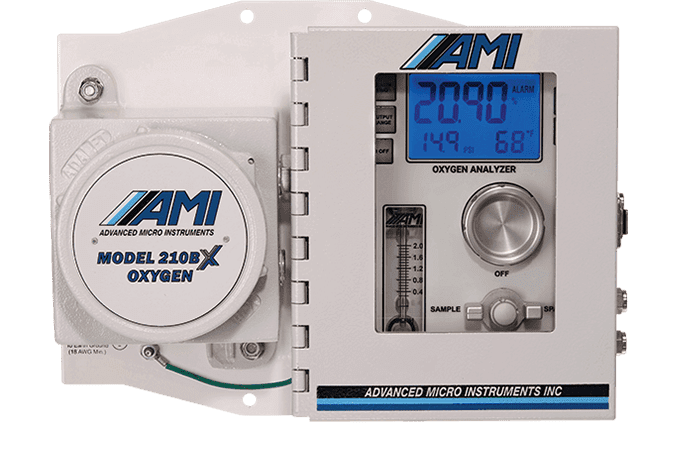

Advanced Micro Instruments offers gas analyzers to monitor oxygen, hydrogen sulfide and moisture levels in the gas streams as well as the conditions within the anaerobic digestors. AMI’s 2010BX, 3010BX, and 4010LX analyzers can monitor percent to trace (ppm) levels of gas constituents and provide alarms or relay outputs for process optimization and control. They are commonly used to verify gas quality at custody transfer points as well as to monitor the operation of moisture and H2S pretreatment equipment.

Biogas from Manure

Livestock waste can be a substantial source of feedstock for biogas operations. A 1,000 pound dairy cow will produce and average of 80 pounds of manure a day. Poultry and sheep will also produce large amounts of waste that must be disposed of. Manure will produce methane, a greenhouse gas, as it decomposes, and run-off from livestock operations has been linked to high nitrogen levels within inland waterways. When livestock manure is recycled through anaerobic digestion it reduces methane emissions, odors and pathogens associated with manure lagoons or stockpiles. The resulting biogas can be used on the farm for energy production and the residual solids can be used in farming for animal bedding and high-quality fertilizer.

Biogas from Landfills

Landfill gas (LFG) is a natural byproduct of the anaerobic digestion of organic material buried in the landfill. Raw landfill gas is approximately a 50-50 mix of methane and carbon dioxide with small amounts of other gasses such as H2S, nitrogen as siloxane. Emissions from landfills can be captured and converted into useable biogas. The landfill gas is captured bye extraction wells and piping to transport it to further processing. Some landfill gas may be flared but depending on the intended use the gas can be upgraded to fuel vehicles or injected into pipelines. The recovery and use of landfill gas represents the largest potential source of biogas in the United States.

Biogas at Sewage Treatment Facilities

Biosolids are a natural byproduct of wastewater treatment. Wastewater utilities have long used anaerobic digestors to kill the pathogens in biosolids and make them safe for disposal. The methane produced in the digestors had traditionally been flared or vented to atmosphere. More recently, however, there has been growing efforts to recover the energy from the wastewater biosolids by capturing and reusing the methane within the digesters. The recovered energy can be used to generate heat or electricity utilized within the wastewater treatment plan or it can be further upgraded for injection into gas pipelines.

Due to the preexisting investment in large anaerobic digestors many sewage treatment plants are also taking in other organic wastes from the surrounding communities. These materials can include food waste and fats, oils and grease (FOG) that is collected from grease traps. This process of co-digestion diverts these materials from landfills and creates and energy rich waste stream for production of biogas.