The Definitive Guide To Percent Oxygen Measurement

Why Measure Percent Oxygen?

In many industrial processes, oxygen concentrations must be kept within established ranges. Strict tolerances in production or quality check points can force a line to stop until the oxygen levels are brought back into range. Companies, including those in natural gas, aerospace, air separation and electronics, utilize Percent Oxygen Analyzers not only to help them monitor their processes but also the mitigation steps if they become necessary.

Types of Electrochemical Percent Oxygen Analyzers

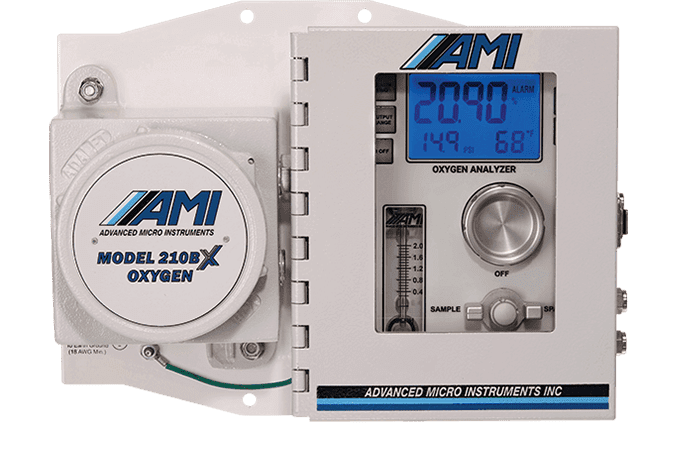

Percent Oxygen Analyzers are available in 3 types of configurations.

Analyzer Design – Things to Look For

With many designs available for Percent Oxygen Analyzers, it may be difficult to understand how one manufacturer’s line compares to another. Though an Analyzer design involves many components, some are more important and have a greater impact on the unit’s performance and measurement reliability.

Sample Handling Components

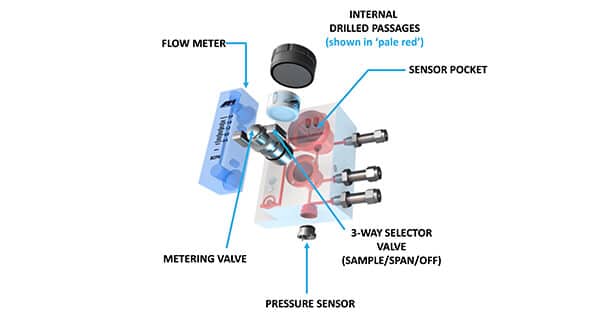

For a Percent Oxygen Analyzer to properly move sample gas to the sensor pocket for measurements, it must contain all critical sample handling components and have these connected to the sample gas path. Among these are the flow meter, metering valve, tubing and selector valve for gas flow. Some designs will even include additional items, such as a pressure sensor and temperature transducer. In considering any Percent Oxygen Analyzer, make sure that the unit contains all the above-mentioned items on this checklist.

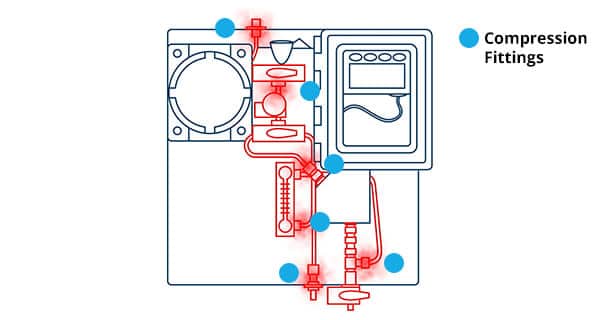

compression fittings are prone to leaks.

Susceptibility of Leaks in the Gas Path

The designs of many manufacturers are reliant on compression fittings. Though they are widely used to connect the sample handling components to the gas path, they are prone to leaks over time and can reduce the performance of the Analyzer.

Innovative designs that avoid the use of compression fittings are a better alternative.

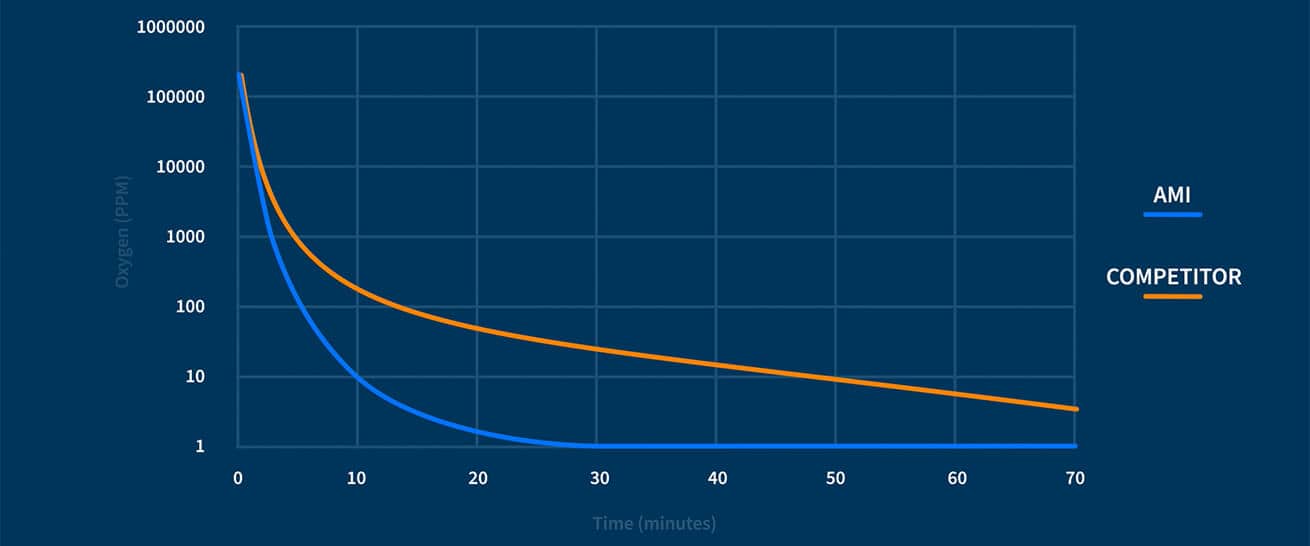

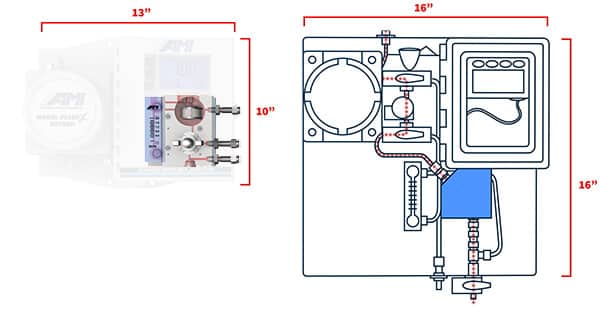

a much shorter gas path.

extends the gas path.

Length of the Gas Path

Getting fast measurements is one of the most important performance metrics in an Analyzer. It is heavily influenced by 2 variables, one of which is the length of the gas path. A shorter gas path delivers a faster reading, while a longer one does the opposite. Understand that a gas path, consisting of several turns and detours prior to reaching the sensor, can be much longer than an Analyzer’s published dimensions.

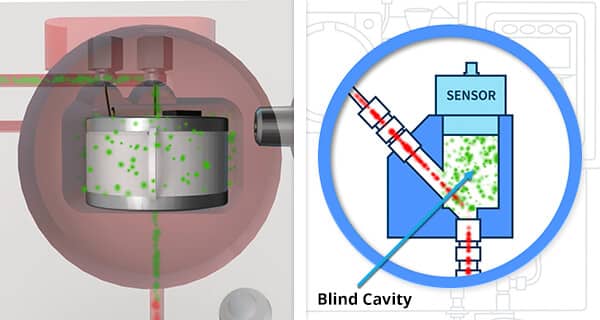

Flow Efficiency of the Sensor Pocket (for Analyzers utilizing sensors)

The other parameter of an analyzer design that affects getting fast measurements is the flow efficiency of the sensor pocket. A good design will allow a rapid and full purge of the sensor pocket. This will allow the sensor to respond quickly and detect any changes in the sample gas. In contrast, a poorly design pocket can have a ‘blind cavity’ that limits the exposure of the sensor to the sample gas and create ‘dead legs’ which slows the exit of ‘previous sample gas’ from the sensor area. Therefore, make sure to evaluate the design of the sensor pocket in your evaluation.

Sample Conditioning & Maintenance

the sample gas prior to it entering the Analyzer.

Analyzers can be sometimes be taken offline due to damage, caused by substances found in the gas pipeline. Therefore, it is highly recommended to install devices that preconditions the sample gas prior to its entry. Liquids, glycols and moisture slugs can flood the internal components of an Analyzer if they make it into the Inlet Port. Additionally, hot sample gas must be cooled to ambient temperature prior to entering the unit because liquids can form from subsequent condensation. Last, pressure from the pipeline must be regulated below the stated operational limits of the Analyzer. Proper sample conditioning maintains the performance of the Analyzer and extends its operational life.

for easy replacement.

Sensor replacement is part of the required periodic maintenance. Some designs make it a relatively easy process, while others make it difficult and time-consuming. Keep in mind that a short process is important in minimizing the oxygen sensor’s exposure to air. Prolonged exposure will greatly diminish an electrochemical sensor’s life – even a new one.