The Definitive Guide To Oxygen Deficiency

Why Monitor Oxygen Deficiency?

Pressurized gas cylinders and dewars that store cryogenically liquefied gases are used in countless applications in manufacturing, production, and research. A leak from any of these containers can quickly displace the oxygen in the surrounding vicinity and move levels below dangerous thresholds. This can put personnel at the risk of oxygen depletion or, even worse, asphyxiation.

Any company, laboratory, or university involved in the handling and storage of these containers need to actively monitor the oxygen levels in those areas as a safety precaution. Moreover, the U.S. and other Western countries have regulatory agencies that create and enforce requirements for a safe workplace.

Primary Method to Measure O2 Deficiency

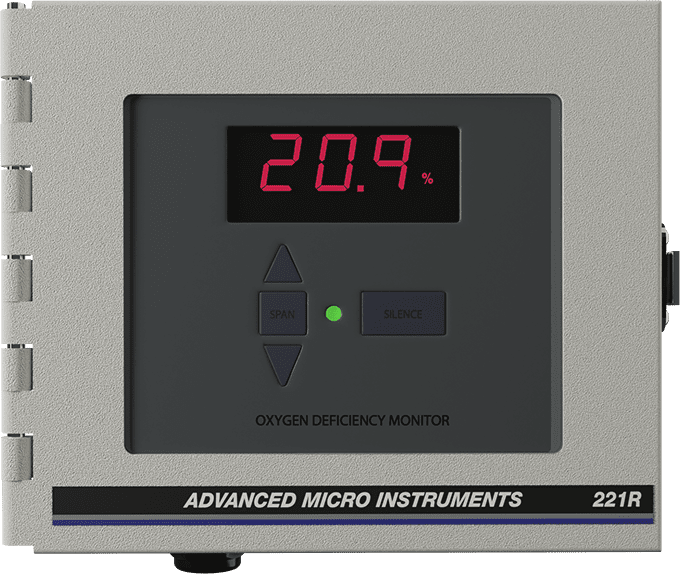

The Oxygen Deficiency Monitor, also known as the Oxygen Deficiency Analyzer, serves as the ideal solution for this application. The unit will generally feature audible alarms and adjustable setpoints to alert people to exit the area when the oxygen suddenly drops below predetermined levels. There are many monitors available on the market, and competing manufacturers differentiate their offering through performance, various programming and ease-of-use features.

Most Oxygen Deficiency Monitors utilize sensor-based measurement technology with the electrochemical sensor and zirconium-oxide sensor being the most popular. However, there are key performance differences that separate these two competing approaches. The next section will discuss this information in more detail.

Electrochemical Sensor vs Zirconium Oxide Sensor

Because accuracy is the main metric for performance, the Analyzer needs to resist drifting when measuring ambient air of any room. In fact, if the unit drifts too far, it can inadvertently trigger a false alarm and cause an unnecessary rush to exit the area. Temperature and pressure fluctuations are often behind incidents of drifting. Some common examples include a sudden weather pattern change and even the cycling operation of an air conditioning system as it turns on and off.

Testing has shown that a zirconium-oxide sensor provides better stability. This is observed in settings, involving both temperature and pressure fluctuations. On the other hand, an electrochemical sensor performs poorly when introduced to the same variables due to its inherent sensitivities.

OSHA Guidelines

Companies operating in the U.S. must comply with guidelines published by OSHA. The information below summarizes what OSHA has established for acceptable oxygen levels in the workplace and when those levels become dangerous:

- Normal air contains about 20.9% oxygen

- Any atmosphere with the oxygen level equal to or less than 19.5% by volume is deemed oxygen-deficient and immediately dangerous to life or health

- Any atmosphere with the oxygen level equal to or more than 23.5% by volume is deemed oxygen-rich

More information can be found on OSHA’s website:

OSHA.gov