What is Cryogenics?

Cryogenics is the use of very low temperatures for medical, commercial, scientific, and industrial applications. Very low temperature in cryogenics can typically be defined as temperatures below -180°C. Cryogenic techniques are employed in applications such as food preservation, storage of biological specimens for reproductive assistance, destroying cancer cells in medical surgeries, or cooling natural gas for transportation.

Cryogenic liquids, due to their very low boiling points, are most often utilized to achieve the low temperature atmospheres. Liquid nitrogen is the most commonly used cryogenic liquid; however, other gases in their liquid state, such as helium, oxygen, hydrogen, neon and methane, are also employed for specific applications.

Cryogenics in Food Processing and Preservation

Food materials are perishable by nature, and care must be taken to preserve food during processing and for storage. Freezing food for storage and transport is a well-established method of preservation. Beyond food freshness and safety, there are several factors that can affect the food’s quality when it is prepared for consumption.

The basic process of freezing all food involves freezing the water within the food versus freezing the product itself. The speed at which the food freezes will dictate the size of the ice crystals that forms within the food. The faster the freezing process, the smaller the crystals, which results in better quality and texture of the frozen food.

Mechanical freezer equipment is the traditional method of freezing foods. This involves large freezers that typically use ammonia as the refrigerant in a mechanical refrigeration cycle, comprised of a compressor, evaporator and condenser. They will operate at -30° F. These systems can be more efficient and cost-effective for long term installations and can be well-suited for high volume requirements. Mechanical freezing equipment will, however, have a much higher capital cost and typically not freeze food as quickly as cryogenic freezing.

Cryogenic freezing is an option to rapidly freeze food using liquid nitrogen or carbon dioxide. This method involves spraying the food with refrigerant or immersing it in liquid N2 or CO2. With typical temperatures of -130° F for liquid nitrogen and -80° F for liquid CO2, the food will freeze almost instantly. This process will limit dehydration and form smaller ice crystals, thus, preserving the product’s texture and flavor. Cryogenic freezing has a lower upfront capital cost, but the refrigerant used is lost to the atmosphere. This means the ongoing operating costs for potentially large volumes of liquid nitrogen or carbon dioxide can be significant.

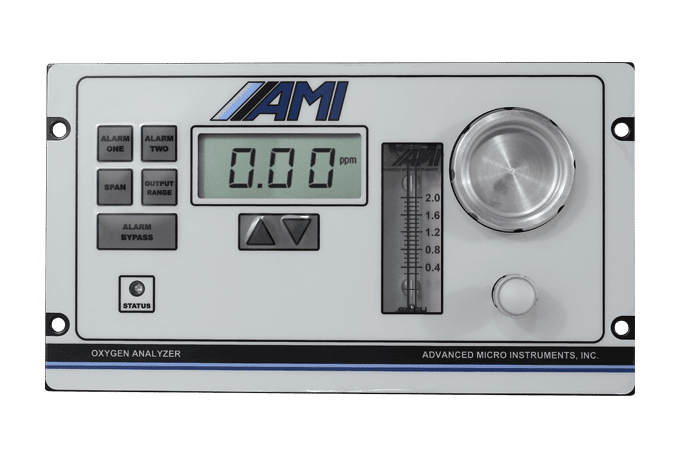

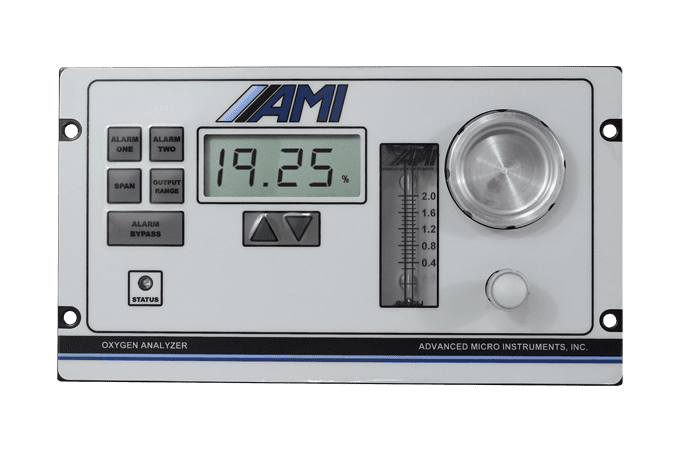

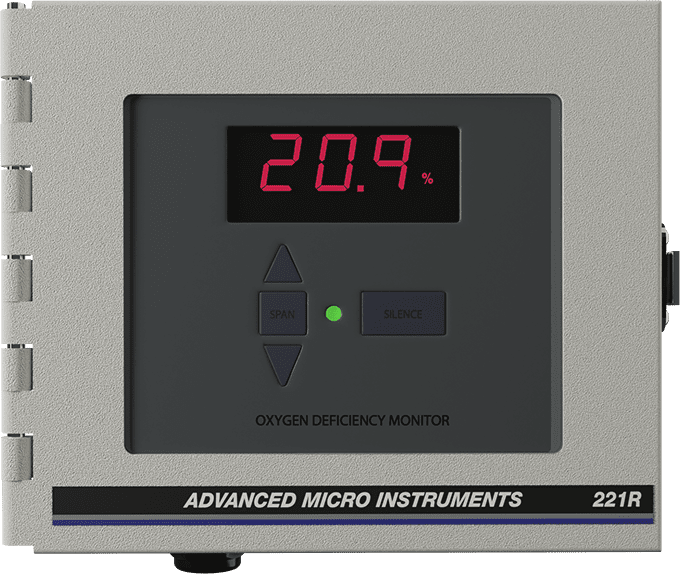

Extreme care must be taken when using cryogenic liquids in food processing applications. High volume food processing requires large quantities of liquid nitrogen or carbon dioxide when stored on site in bulk storage tanks. If there are any leaks or unexpected releases of these cryogenic liquids, it can be very harmful to people in the area. When liquid N2 or CO2 converts to a gas as it is released into the air, it is colorless and odorless. In this form, it has the capability to displace the oxygen within the work area, putting employees in danger. AMI’s 221R Oxygen Deficiency Monitor is an excellent choice for monitoring the work areas as well as storage areas from the potential hazards of these cryogenic gases.

Cryogenic Liquid Safety

Cryogenic liquids or cryogens are essential for many processes, but using them is not without its potential hazards. Different cryogens will transition from liquid to gas phase at different conditions of temperature and pressure, but they all have two common properties that can create hazardous situations – they are extremely cold, and small amounts of the liquid can expand into very large volumes of gas.

The use of cryogenic liquids can pose one or more of the following hazards:

- Burns from Extreme Cold: Cryogens in both liquid and gas phase exist at extremely low temperatures. Even very brief exposure can cause burns to the skin and eyes. Full body covering, including face coverings and properly insulated gloves, should be used to prevent exposure from handling or splashing of cryogens.

- Material Embrittlement: Plastics, carbon steel, rubber or other materials that are normally pliable at room temperature can become brittle and break when in contact with cryogenic liquids.

- Pressure Build-up/Explosion: Cryogenic liquids can expand to large volumes of gas, resulting in a rapid change in pressure. If adequate volume is not available for the gas to expand into or vent, there is a risk of explosion. Safe storage and handling should include insulated vessels, and all containers should have a functional pressure relief valve.

- Accelerated Combustion: Beyond traditionally flammable gases like methane and hydrogen, oxygen gas in high concentration can create combustible or explosive environments. Oxygen by itself is not flammable, but liquid oxygen or an oxygen-enriched environment in contact with flammable or organic materials, such as oils, grease, or cotton clothing, has the potential to explode or start a fire.

- Oxygen Deficiency/Asphyxiation and Oxygen Enrichment: Cryogenic liquids can quickly transition to the gas phase and displace the normal atmosphere within a work environment. This can result in an oxygen-deficient environment within a confined space. The lack of oxygen can render a person unconscious within seconds and result in death within a few minutes. Liquid oxygen also has the potential to enrich an enclosed area, causing an unhealthy environment as well as a potentially explosive atmosphere.

Safe storage and handling of cryogenic liquids requires the right equipment, materials and safety protocols. Critical to protecting workers is having the ability to detect unintentional gas releases that result in a dangerous atmosphere. AMI’s 221R Oxygen Deficiency Monitor will alert personnel to both oxygen-deficient and oxygen-rich environments with an audible alarm and allow for the activation of ventilation fans or other safety systems.

What is Whole Body Cryotherapy?

Cryotherapy or cold therapy is the use of low temperatures in the treatment of medical conditions. Cryotherapy has been used for many years by doctors to treat localized skin conditions, such as warts and skin cancers as well as targeted invasive cancer treatments. More recently, whole-body cryotherapy has gained popularity as a spa treatment for a wide range of ailments, including muscle soreness, migraines, and arthritic pain.

Whole body cryotherapy involves quickly chilling the body with extremely cold temperature for a short period of time. This is achieved by the patient entering an open chamber and then introducing liquid nitrogen. As the nitrogen mixes with air in a gaseous form, the environment around the patient drops rapidly to between -150°C to -180°C. The 3-5 minute exposure of the patient’s bare skin to the cold temperatures provides reported therapeutic benefits.

Whole-body cryotherapy is typically performed in a commercial spa or health club setting. Safety of the patients and staff is of critical importance. This includes proper operations of cryotherapy equipment as well as proper training and protocols for safely handling liquid nitrogen. Part of the safety protocols should include an oxygen deficiency monitor such as AMI’s 221R. The O2 deficiency monitor will warn staff if nitrogen has leaked into the building and lowered the oxygen in the atmosphere to unsafe levels.

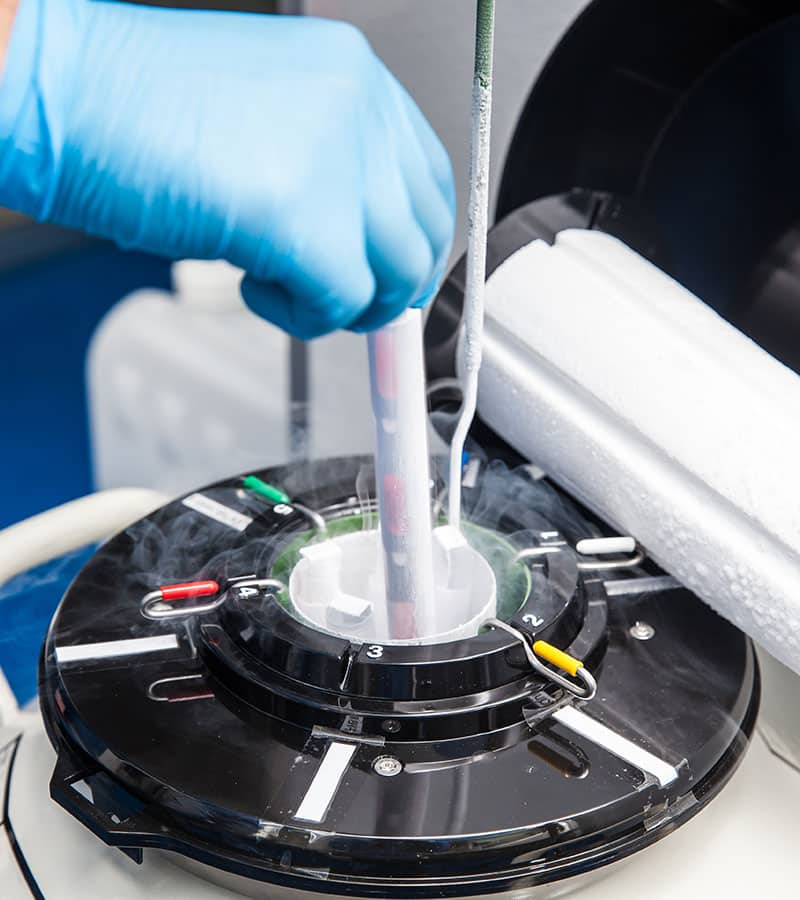

What is Cryopreservation?

Cryopreservation is a scientific process of preserving tissues, cells and other biological items at very low temperatures. It is an important technique for today’s routine scientific research as well as being integral to many medical processes, such as assisted reproduction, cell level transplantation and biomarker therapies. The techniques for cryopreservation are specific to the chemical and physical properties of the target biological samples. Success is dependent on precise control of the temperature, the rate of freezing, and the use of cryoprotective agents, which affect the formation of ice crystals and water migration within the cell structure.

While the techniques of cryopreservation are developed in a lab environment, they must often be transferred safely to a larger scale in clinical or manufacturing settings. Liquid nitrogen is the most common cryogenic liquid used to achieve the cold temperatures at any significant scale. A clinical location with production quantities of liquid nitrogen on premises should always have an oxygen deficiency monitor like AMI’s 221R Oxygen Depletion Monitor. A leak in the storage or distribution system or an unplanned release of the inert gas can quickly displace the normal atmospheric oxygen and create an unsafe environment for personnel in the area. The oxygen deficiency monitor will detect low oxygen levels in the atmosphere and sound an alarm to alert individuals in the area to the danger.