Why Use Panel Mount Oxygen Analyzers

Oxygen concentrations must be kept at specified levels in many industrial processes involving manufacturing and quality. If the levels move outside of the tolerance range, the company must carry out steps to bring the concentrations back to within specifications. This can involve the introduction of nitrogen or another inert gas or some other mitigating process. Failure to do so will either halt production or result in product that will not pass quality control.

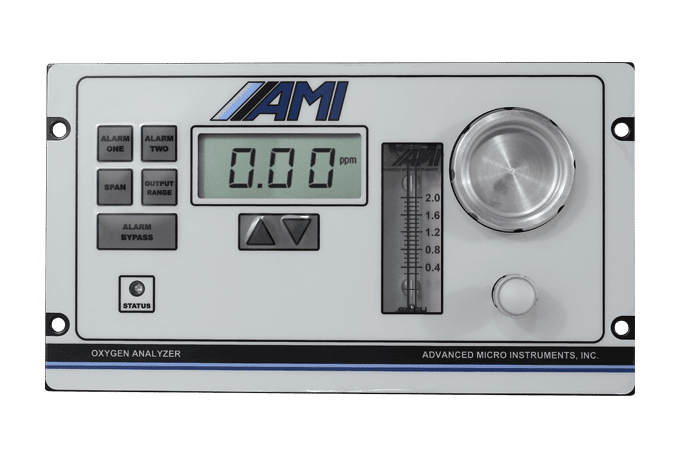

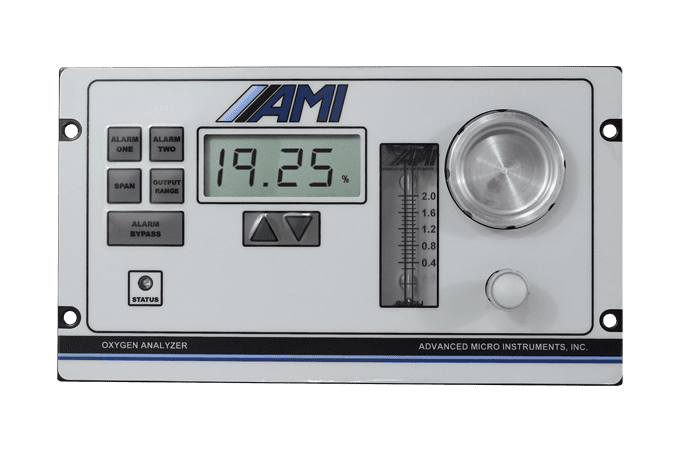

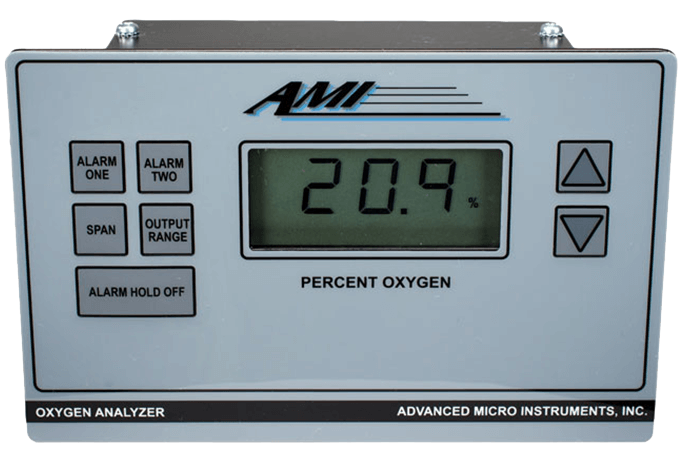

Panel Mount Oxygen Analyzers are available for both trace oxygen and percent oxygen measurements. Though the majority will utilize electrochemical oxygen sensors, there are some that employ zirconium-oxide sensors.

The inclusion of certain features with the Analyzer can be extremely helpful. One such feature are solenoid valves. These valves allow the operator to immediately seal the oxygen sensor inside the Analyzer once the production process has finished. This prevents outside air from contaminating the sensor and shortening its life when the sensor is not in use. Otherwise, the company must have a solution in place that completely blocks both the inlet and exhaust ports. The other notable feature is a pump, which comes in handy when the line requires positive pressure to move sample into the Analyzer.

The selection of the right Panel Mount Analyzer will depend on the requirements of the measurement application. The operator will also need to weigh-in the value of having solenoid valves and a sample pump as well as other standard or advanced features that may come with a specific Panel Mount Analyzer model.