The Critical Role of Gas Analysis in Biogas and RNG Production

Companies producing biogas and renewable natural gas utilize gas analyzers for multiple purposes. Analyzers play a crucial role in ensuring both efficient production and the safety and efficacy of the finished product.

The Distinction Between Biogas and RNG

The terms biogas and RNG are sometimes used interchangeably; however, they refer to distinct products. Biogas is the raw gas produced from organic waste. RNG refers to the refined, high-quality product obtained from biogas that is ready for commercial distribution and sale.

- Biogas is a renewable energy source produced from various sources of organic waste. Producers utilize an anaerobic digester to produce the biogas. Feedstocks to the digester can include manure, municipal wastewater sludge, and other organic materials. Organic materials can be procured from agricultural, food, industrial, and green waste sites.

- RNG is upgraded biogas that meets pipeline-quality standards for injection or use as vehicle fuel. RNG is chemically similar to fossil natural gas, but is derived from renewable sources.

- The primary components of biogas and RNG are Methane (CH₄) and Carbon Dioxide (CO₂).

- Trace components, including Hydrogen Sulfide (H₂S), Oxygen (O₂), Nitrogen (N₂), Ammonia (NH3), Moisture (H₂O), and Siloxanes, are also present in biogas and RNG.

- Commercial applications of biogas and biomethane include electricity generation, heat production, and the production of vehicle fuel. Additionally, RNG can be injected into the natural gas pipeline grid. Each application requires a different level of processing and purifying, with sales gas receiving the highest level of treatment.

Why is Gas Analysis Crucial in Biogas?

Biogas producers achieve the following benefits by leveraging practical gas analysis.

- Process optimization: Analysis ensures efficient microbial activity and maximum methane yield. Analyzers can provide real-time operational data, allowing teams to make necessary adjustments to the process and maintain optimal production levels.

- Equipment protection: Proper analysis can prevent corrosion and damage to engines, boilers, and processing equipment, extending their life and minimizing production costs.

- Product quality assurance: Analysis is critical in meeting stringent pipeline injection and end-use specifications for commercial applications.

- Safety: Analyzers enable the detection of hazardous gas levels, including explosive methane and toxic H₂S.

- Odor Control: Analysis is used to measure and control H₂S levels, preventing nuisance odors in communities and ensuring regulatory compliance.

- Compliance: Analysis is required to comply with environmental regulations and industry standards.

Introducing AMI: Your Partner in Precision Biogas Gas Analysis

AMI has been committed to reliable gas measurement since 1995. We began with a vision to develop a superior trace oxygen analyzer compared to market alternatives. Our revolutionary designs and advanced technologies, such as the proprietary eliminator cell block, enable us to offer our customers reliable gas analyzers that provide impressive functionality and features at an attractive price point.

We specialize in analyzers and equipment for measuring oxygen (O₂), hydrogen sulfide (H₂S), and moisture (H₂O) during biogas production and upgrading to produce pipeline ready RNG. AMI is a leader in the industry for monitoring trace levels of O₂, H₂S, and moisture in natural gas for upstream and midstream pipeline operators. Our equipment plays a crucial role in protecting infrastructure and personnel throughout pipeline operations as well as industries such as aerospace, electronics manufacturing, and air separation.

AMI’s proprietary Command Center software platform streamlines the use and management of our analyzer line. We partner with our customers, providing exceptional service and post-sales support to maximize the value of our solutions for your business.

AMI Gas Analyzers: Solutions for Every Stage of Biogas Production

AMI’s gas analyzers provide producers with practical solutions that cover all stages of biogas production and various usage scenarios.

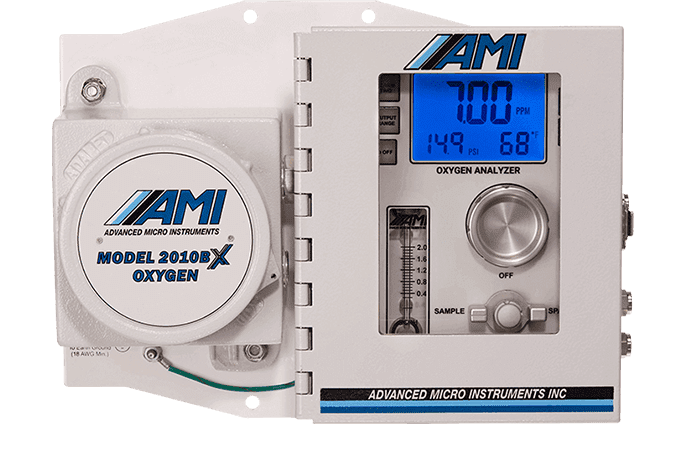

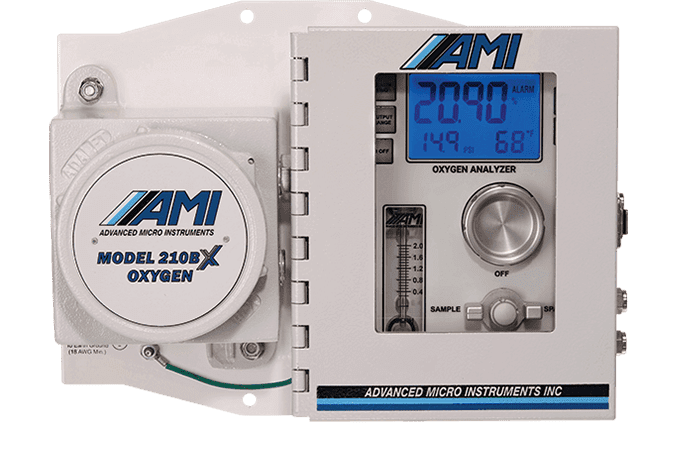

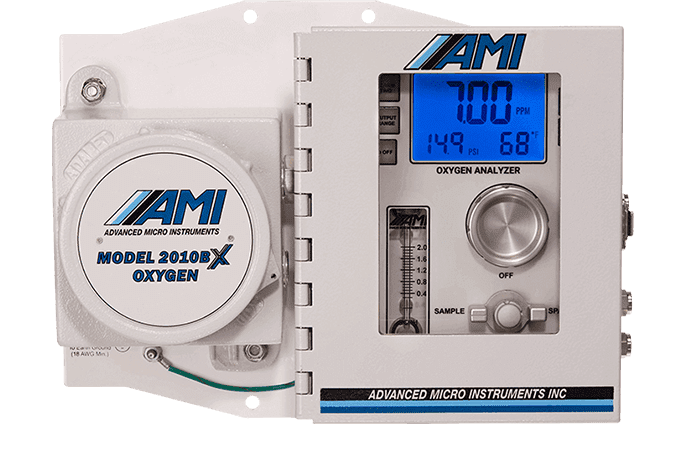

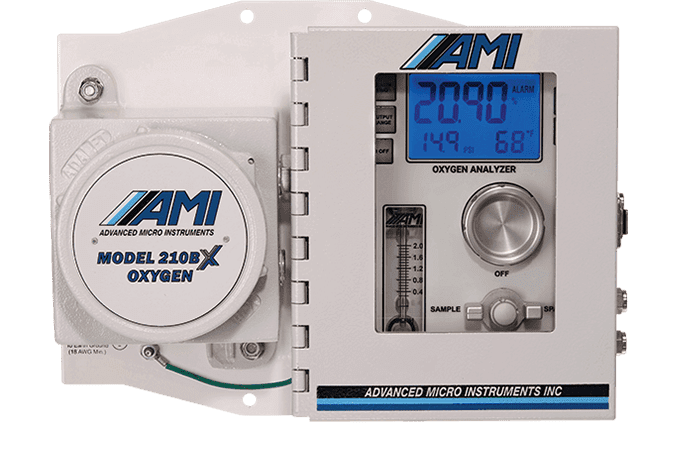

Permanent Mount Oxygen Analyzers

Models: Model 2010BX, Model 210BX, Watchdog

Applications of permanent mount oxygen analyzers include:

- Evaluating the quality of raw biogas.

- Ensuring consistent anaerobic conditions throughout the process.

- Monitoring oxygen levels remain under explosive levels during biogas upgrade process.

- Ensuring oxygen is not leaking into the biogas stream and contaminating the product.

- Post-upgrading for final product quality and custody transfer.

Key Features of our permanent-mount oxygen analyzers include high accuracy, reliability, rapid response, ease of operation, and suitability for use in hazardous areas (Class 1, Div. 1).

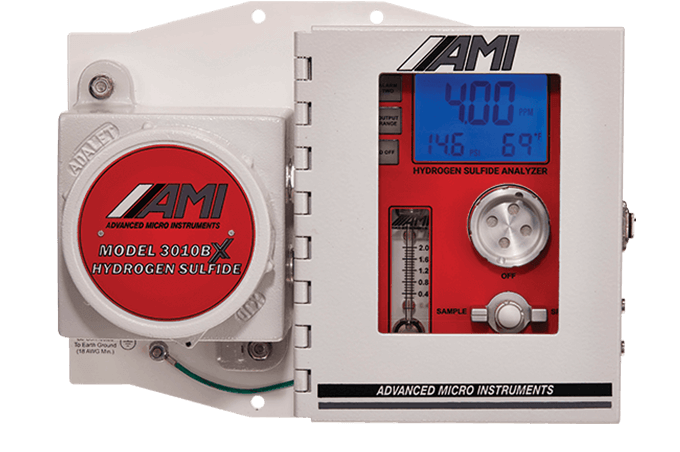

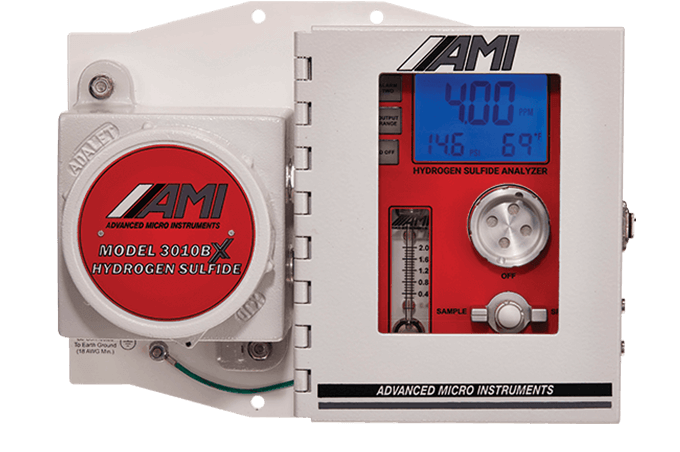

Permanent Mount H₂S Analyzers

Model: Model 3010BX

Applications of permanent hydrogen sulfide (H₂S) analyzers include:

- Monitoring the pre-desulfurization process for incoming gas before treatment at levels up to 2000ppm.

- Verifying the post-desulfurization process of outgoing gas to ensure efficient H₂S removal.

- Preventing corrosion in equipment and pipelines.

- Controlling undesirable odors.

The following are the key features of the Model 3010BX.

- Suitability for use in hazardous areas (Class 1, Div 1).

- Real-time, continuous data is provided for effective and consistent H₂S analysis.

- Greater accuracy than competitive single-use stain tubes that are subject to sampling errors due to subjective ready methods, and more cost-effective than single-use tubes that can add up in expense over time.

- Low-maintenance design featuring no moving parts and a single, easy-to-replace sensor, unlike competitive tape-based systems that require monthly maintenance and frequent calibration due to their complex mechanical components.

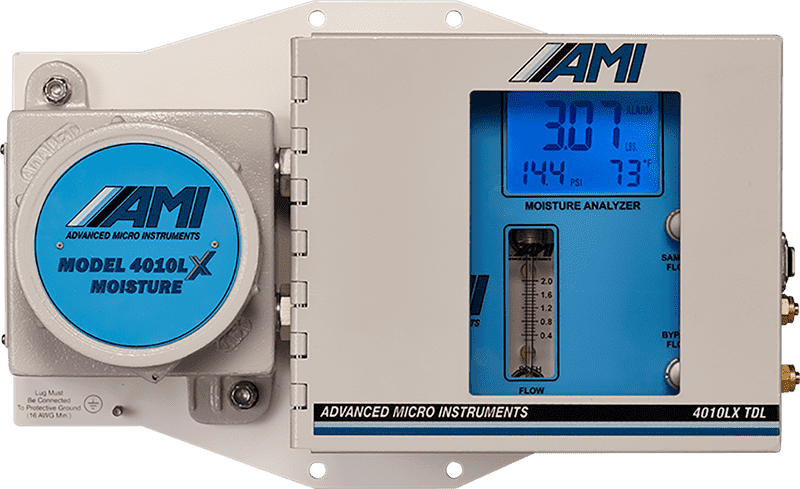

Permanent Mount Moisture Analyzers

Model: Model 4010LX

Applications of our permanent mount moisture analyzer include:

- Monitoring gas dryness before the compression and upgrading processes.

- Ensuring pipeline specifications for moisture content.

- Suitability for hazardous areas.

- Protecting sensitive equipment from corrosion.

Key Features of the 4010LX are its tunable diode laser measurement for accurate trace moisture detection, easy-to-operate and maintain design, fast measurement response, and IP-65 rating, making it suitable for demanding environments.

Portable Analyzers

Models: Model 3000BX portable H₂S Analyzer, Model 1000BX portable O₂ analyzer

Applications of the portable models include:

- Spot-checking various points in the system for safety and efficiency.

- Identifying leak points.

- Performing troubleshooting and maintenance activities.

- Streamlining verification during the commissioning process.

- Performing temporary continuous monitoring when a permanent mount analyzer is not available.

Key Features of the Model 3000BX & Model 1000BX portable analyzers include their mobility, speed, data logging capabilities, and accurate and repeatable measurements, making them an ideal solution for field use.

Software and Accessories

AMI’s ecosystem supports comprehensive monitoring and data management with the following software and hardware components.

- Command Center: The Command Center interface software is a specialized electronics platform that operates across all AMI Gas Measurement Analyzers, providing customers with access to advanced functions not available on competitive devices. The Command Center includes analyzer information, streamlines security settings, alarm setup and control, error status, sensor status, and datalog configuration.

- Sensors: AMI offers customers advanced H₂S and O₂ sensors designed to support your specific applications. We also manufacture electrochemical sensors to measure oxygen in flammable gases.

- Sample conditioning is an essential process in biogas and RNG production. AMI has dedicated sample conditioning solutions. The Demister is a compact device that attaches to the pipeline to rapidly cool hot sample gas, draining liquids back into the pipeline to protect your analyzers. Our Analyzer Guardian provides simple and effective protection against liquids entering the gas analyzer.

- Extreme Weather Enclosure: When the cold weather performance of the 2010BX, 210BX, 3010BX, and 4010LX needs to go lower, installing these analyzers in an Extreme Weather Enclosure provides additional insulation and protection, allowing them to operate at colder temperatures.

The Biogas Production Process: Where Gas Analysis Intervenes

The process of producing RNG starts with the production of raw biogas. Biogas has applications as an engine fuel or for heating without being upgraded. Upgrading raw biogas to sales gas enables it to be used in pipelines for widespread commercial use.

Anaerobic Digestion: The Core Process

Anaerobic digestion is the process used to process raw materials into biogas. This transformative process relies heavily on the composition of these raw materials and the environmental conditions in which they are processed.

- Overview of Feedstocks: The process begins with organic feedstocks, including agricultural waste (such as manure and crop residues), municipal wastewater, food processing waste, and landfill organics. Biogas production relies on the wide availability of these materials.

- The Transformation Process: Transformation occurs in an oxygen-free (anaerobic) environment, such as a digester, where microorganisms break down the organic matter, releasing a mixture of gases primarily composed of methane (CH₄) and carbon dioxide (CO₂).

- Importance of a Controlled Environment: The efficiency of gas production and the quality of the resulting biogas are highly dependent on maintaining optimal conditions within the anaerobic digester. For example, even trace levels of O₂ can severely impact digester performance.

- AMI’s Role: Gas analyzers monitor key parameters, such as trace O₂ ingress, to ensure the anaerobic environment remains stable, thereby protecting the microbial communities responsible for gas production.

Raw Biogas Composition and Variability

Biogas is primarily composed of methane (CH₄) and carbon dioxide (CO₂), and also contains small amounts of other gases, depending on the substrate and conditions used in its production. The typical ranges for these gases are 50%- 75% for CH₄ and 25%-50% for CO₂. Methane is the most valuable component, providing a significant source of fuel for combustion and electricity generation.

Factors such as the type of feedstock, temperature, soil pH, and nutrient variability all affect raw biogas composition. These factors can substantially impact the range of components in raw biogas.

AMI’s role in the process is to perform initial raw biogas analysis to understand the impact of feedstock on digester performance. Based on this analysis, producers can make informed decisions and the necessary adjustments to optimize production.

Biogas Impurities and Their Impact Across the Production and Upgrading Process

Impurities must be minimized or eliminated to ensure efficient biogas production and subsequent biomethane upgrading. Producers must address the following impurities effectively to optimize biogas production and upgrading.

Hydrogen Sulfide (H₂S)

Impact on Production

Hydrogen sulfide is highly corrosive to on-site CHP engines, piping, and instrumentation. It is toxic to personnel and can cause odor complaints from nearby entities.

Impact on Upgrading/RNG

Producers must scrub H₂S levels to less than 4 ppm, and in some cases below 0.25 ppm, to meet strict pipeline injection standards and prevent corrosion in the natural gas grid. Low levels of H₂S are essential for quality verification in custody transfer.

AMI’s Solution

The fixed-mount H2S analyzer, Model 3010BX, and portable H2S analyzer, Model 3000BX, provide continuous and accurate measurement at multiple points in the process. H₂S levels can be measured before and after desulfurization in production, and again to verify final product quality after upgrading.

Moisture (H₂O)

Impact on Production

Moisture causes corrosion (especially when combined with H₂S and CO₂). It can also lead to freezing and blockages in gas lines in colder climates, which can disrupt engine operation.

Impact on Upgrading/RNG

Moisture must be removed to meet pipeline dew point specifications designed to prevent condensation and corrosion in the pipeline. Dry gas is also a critical specification for vehicle fuel (CNG) and cryogenic upgrading processes.

AMI’s Solution

We offer the permanent-mount moisture analyzer, Model 4010LX, to monitor dryness after biogas upgrading, preventing issues and ensuring final product compliance.

Oxygen (O₂)

Impact on Production

The presence of oxygen indicates air ingress into the digester, posing a safety hazard due to the potential for explosive mixtures. Oxygen also inhibits the growth of methanogenic bacteria, reducing biogas yield and quality.

Impact on Upgrading/RNG

Oxygen levels are a critical purity parameter for pipeline gas. High O₂ content can indicate a leak in the upgrading system or pipeline and can degrade the gas quality, for example, through oxidation. Strict limits on O₂ levels (often < 0.5% - 1.0%) are universally enforced.

AMI’s Solution

Our trace and percent level oxygen analyzers (e.g., Model 2010BX, Model 210BX, Model 1000BX) detect minute levels in the digester for process control and at the final output, ensuring safety and compliance with pipeline specifications.

Other impurities, such as siloxanes and nitrogen, must be removed to minimize their impact on engines and meet standards for calorific value and equipment protection. Producers must perform a comprehensive analysis throughout the process to monitor and control these impurities.

Biogas Upgrading and Conditioning: Transforming Raw Biogas into Valuable Sales Gas

From Raw Biogas to Renewable Natural Gas (RNG): A Two-Step Journey

- Raw biogas from the digester can be used directly on-site for electricity generation, via CHP engines, or for heating. If the end destination for the biogas is a natural gas pipeline, known as Renewable Natural Gas (RNG), the biogas must be strictly cleaned and upgraded to remove impurities.

- The upgrading process can increase methane concentration, resulting in a higher energy value and a more profitable commercial product.

- Upgrading removes impurities to meet pipeline specifications for biomethane and protect downstream equipment.

- RNG is a green energy source that captures methane from waste sources, such as food waste, manure, garbage, and wastewater solids, and repurposes it as a fuel.

Key Upgrading Technologies

Multiple technologies are involved in the upgrading process.

- Water scrubbing is a process used to remove contaminants or unwanted substances from a gas stream by passing it through water. It relies on the solubility of gases in water to clean the gas.

- Pressure swing adsorption (PSA) is a gas separation technique that relies on the properties of adsorbents to selectively adsorb gases under high pressure and release them under low pressure. It is used to remove carbon dioxide from methane in the RNG upgrading process.

- Membrane separation utilizes a semi-permeable membrane to separate gas components based on their physical and chemical properties, such as shape, solubility, or molecular size.

- Chemical Absorption absorbs gas into a liquid through a chemical reaction between the gas and a component of the liquid. The process is based on molecular bonding.

- Cryogenic Separation separates gases by cooling them to very low (cryogenic) temperatures, leveraging the different boiling points at which individual gases condense or liquefy.

AMI’s Role Across Upgrading Stages

AMI’s technology is instrumental in the upgrading stages to ensure biogas is efficiently transformed to sales gas in multiple ways, including:

- Monitoring inlet gas to the upgrading system for pre-treatment effectiveness.

- Monitoring outlet gas to ensure that the desired purity is achieved.

- Continuous monitoring during the process to optimize efficiency and detect issues so they can be addressed effectively.

Meeting Biogas Quality Standards

AMI’s analyzers are essential tools for meeting biogas quality standards. Our analyzers provide the precision and reliability to meet compliance requirements and custody transfer verification.

- Producers must meet specifications for direct use of raw biogas in engines/CHP systems to ensure safe, efficient, and durable operation.

- Upgraded biogas used as vehicle fuel must meet stringent quality standards to ensure optimal engine performance, safety, and compliance with emissions regulations.

- The custody transfer process, where biogas or RNG is transferred between parties, must meet strict quality standards to ensure safety, compatibility, and fairness in billing based on the product’s energy content. Producers must verify that the RNG meets the contractual requirements of pipeline operators.

- AMI’s analyzers can perform multiple roles at the final step of the RNG upgrading process.

- Companies may deploy equipment at the upgrading system itself for continuous monitoring.

- Analyzers can be used in a dedicated injection station or analyzer building to verify compliance before pipeline or virtual pipeline injection.

- AMI’s Advantage: Our analyzers provide the precision and reliability required for compliance and custody transfer verification.

Benefits of Partnering with AMI for Biogas Professionals

Biogas producers enjoy the following benefits from partnering with AMI.

Our analyzers provide the accuracy and reliability that pipeline operators trust.

AMI’s analyzers help producers maximize methane yield, reduce operational costs, and prevent costly downtime.

Companies can protect and extend the lifetime of their equipment by conducting accurate analyses to minimize corrosion and wear.

Producers can ensure regulatory compliance and quality assurance to meet market and environmental demands.

AMI’s focus on safety enhancements enhances the detection of risks associated with explosions and toxicity.

Businesses achieve long-term savings due to the improved efficiency and reduced maintenance of our analyzers.

We design our equipment to be user-friendly, meeting the needs of busy professionals.

Case Studies

The following case studies illustrate some of the benefits of deploying AMI gas analyzers.

How AMI analyzers help biogas plants optimize the desulfurization process.

AMI analyzers can be utilized to help a biogas plant optimize its desulfurization process. Teams perform measurements to verify that the process is working efficiently and to provide a feedback loop, ensuring optimal desulfurization. Customers can continuously monitor the H₂S concentration of the processed gas using the Model 3010BX analyzer or choose to spot-monitor the process with the Model 3000BX.

How to ensure compliance for facilities injecting RNG into the natural gas grid.

Companies typically perform compliance measurement of sales gas at two locations. The biomethane leaving the upgrade plant is tested at the facility in an analytical building to ensure it meets pipeline requirements before being stored. Similar measurements are made when the RNG is delivered to the pipeline injection site, prior to injection taking place. RNG producers utilize our industry-leading Models 2010BX, 3010BX, and 4010LX to ensure compliance at both ends of the pipeline injection process.

How to prevent engine damage in a CHP plant through continuous H₂S monitoring.

Teams using biogas to power a CHP plant must continuously monitor H₂S concentrations to prevent engine damage. H₂S forms sulfuric acid when burned, which can result in corrosion affecting combustion chambers, pistons, and other engine components. The damage is cumulative, and even low concentrations can cause long-term damage to the equipment. AMI’s Model 3010BX provides the continuous monitoring necessary to ensure H₂S concentrations remain low enough for safe engine operation.

How to keep natural gas under explosive limit

Natural gas is not inherently explosive and it takes the introduction of oxygen for it to become so. Therefore, it is important to maintain minimal levels of oxygen to eliminate explosion risks. As RNG upgrading processes have the potential to introduce oxygen into the gas, it is important to monitor oxygen levels throughout the process to verify oxygen levels remain under explosive levels. RNG producers use the Model 210BX to monitor oxygen levels before and after treatment processes where oxygen may be introduced to verify oxygen levels remain under explosive causing concentrations.

Empowering Biogas Professionals with AMI

AMI has been committed to providing the biogas industry with advanced gas analyzers for 30 years. Our technically advanced permanent-mount and portable analyzers are designed to align with usage scenarios throughout the biogas production and upgrading process. We understand that precision gas analysis is not just a production tool, but can also offer your business a strategic and competitive advantage in the dynamic biogas market.

Contact us to schedule a consultation or request a quote.