Need Oxygen Deficiency Monitoring For your Facility Project?

Advanced Micro Instruments can provide you

with Oxygen Safety Monitors that meet OSHA Requirements

Why Contractors Choose

- Easy to Install

- Connects to Building Automation

- On the Shelf and Ready to Ship

- Solid Warranty & Reliability

- AMI Corporate Partnership

Why Facility Owners Need

OSHA Compliant

- Built-in Battery Back-up

- Washdown Ready Enclosure

- Optional Remote Monitoring

- 10-Year Sensor Life

Design Resources

Plan Your Monitor Integration

Request a quote below

Installation of the 221R is a 3-step process that is quick and easy. Watch to see it for yourself!

Connects to Building Automation

The Model 221R can coordinate with other building automation systems. Not only can the alarm relays activate fans or alarms directly, but the 4-20mA and RS485 outputs can be tied into building control systems.

On the Shelf and Ready to Ship

AMI builds units for inventory. This allows us to ship orders the next business day. There is no long wait or lead time before your MODEL 221R units arrive.

Solid Warranty & Reliability

2-year warranty for Parts & Labor for any defects in materials or workmanship. 2-year Warranty for zirconium oxide sensors.

AMI Corporate Partnership

AMI recognizes the importance of collaboration and partnership for success of complex projects or large organizations. By working directly with AMI customers trying to manage multiple sites and/or divisions or implement a project over an extended timeline can benefit from coordinating their activities with AMI.

Our account experts will create a customized program that meets your specific needs, offering you priority service, volume savings and the efficiency of a single account.

The MODEL 221R is ready ‘straight out of the box’ with alarms already preset to OSHA’s critical safety thresholds.

OSHA has established the following guidelines for oxygen level safety:

- Respiratory Protection Standard, 29 CFR 1910.134 - Paragraph (d)(2)(iii) of the Respiratory Protection Standard considers any atmosphere with an oxygen level below 19.5 percent to be oxygen-deficient and immediately dangerous to life or health.

- OSHA 1910.146, and 1926 and Subpart AA - Reference 23.5% as the concentration above which the atmosphere is hazardous because of oxygen-enrichment.

Built-in Battery Back-up

Oxygen safety monitoring must operate 24/7. The 221R includes a built-in battery back-up to ensures no disruptions to monitoring for safe oxygen levels in the event of a power loss.

Washdown Ready Enclosure

Some other deficiency monitors will fail if sprayed with water during a washdown. AMI's 221R is engineered for use in facilities where a washdown is required for sanitary compliance.

Optional Remote Monitoring

The optional remote probe can be ordered for the MODEL 221R and be installed up to 300 ft away from the main console, offering customers installation flexibility for their oxygen monitoring.

10-Year Sensor Life

AMI’s MODEL 221R utilizes zirconium oxide-based sensors for oxygen monitoring. They offer up to a 10-year service life as well as being incredibly accurate, not affected by sudden swings or drifts in barometric pressure, and require minimal maintenance over the life of the sensor.

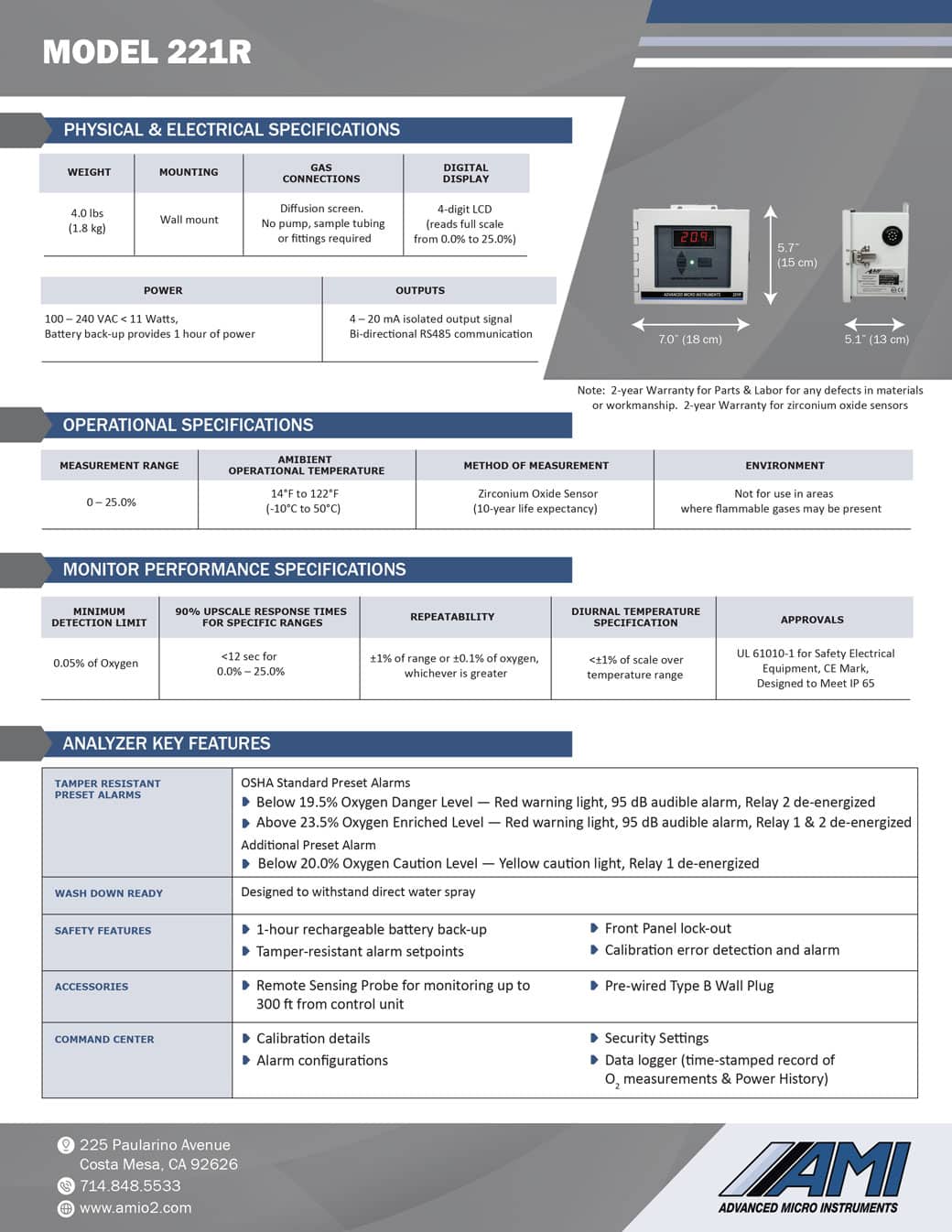

Unit Specifications

Download Unit Specs

Engineering Drawings

Download Engineering Drawings

Guide Specifications

Download Guide Specs

Features & Benefits

Special Safety Features

Rechargeable battery backup with low power alarm, tamper-resistant alarm setpoints to prevent user override, calibrations error detection, and front panel lock-out.

Special Safety Features

The MODEL 221R is certified by a 3rd party testing lab to meets UL 61010-1 Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use.

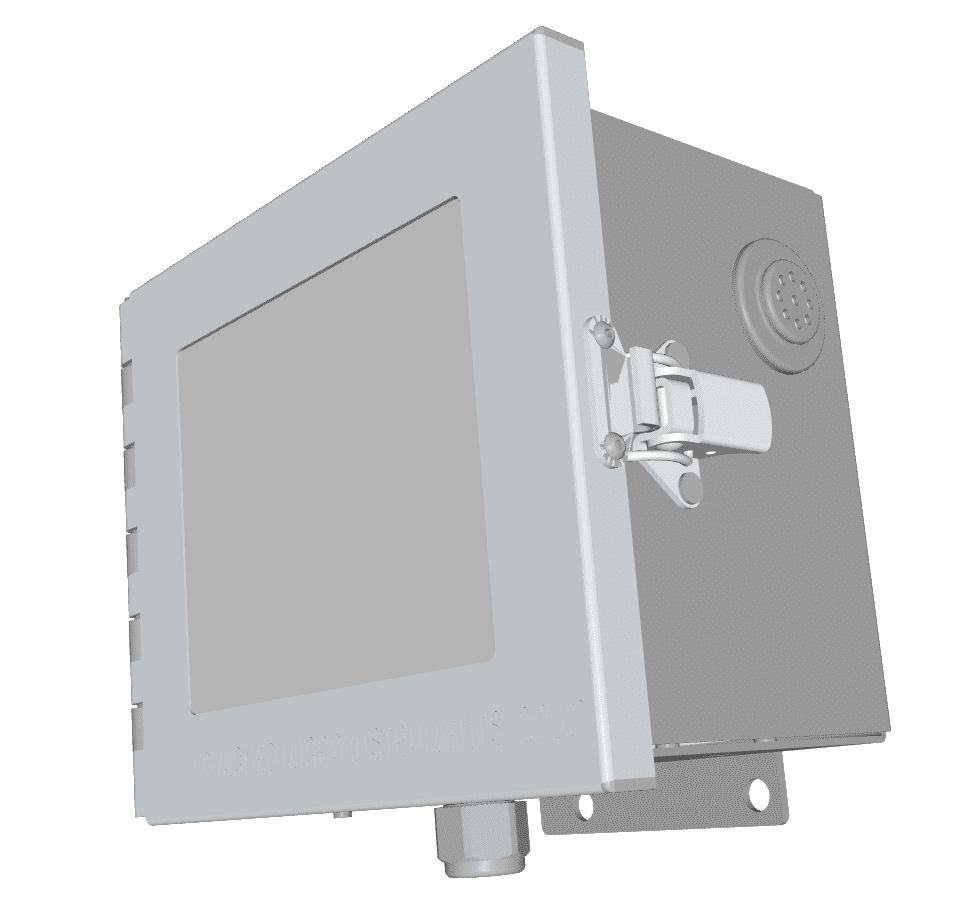

Washdown-Ready Metal Enclosure

The powder-coated aluminum enclosure of the Analyzer is designed to provide protection against ingress of dust and water from low pressure spray. Design protects analyzers in difficult industrial environments and allows for low pressure washdown of the unit.

Audible Alarms & Relays

Detection of an Oxygen-Deficient environment will trigger a 95 dB alarm to warn of danger. Additionally, includes relays for triggering safety beacons or exhaust fans.

Audible Alarms & Relays

Alarms are preset to oxygen levels mandated by OSHA. Normal ambient atmosphere has an oxygen concentration of 20.9%. The OSHA Respiratory Protection Standard 29 CFR 1910.134 states 19.5 percent oxygen as the level below which an oxygen-deficient atmosphere exists and requires, generally, that all oxygen-deficient atmospheres be considered immediately dangerous to life or health.

10-Year Sensor Life

The Zirconium Oxide Sensor provides up to 10-years of operational life while only requiring simple, periodic calibration. Detection technology is IDEAL for monitoring oxygen safety levels. Maintains accuracy over wide temperature range and not affected by changes in barometric pressure.

10-Year Sensor Life

AMI's zirconium oxide sensors provide the best option for monitoring oxygen levels in inert atmospheres due to their stability, limited maintenance and up to 10 years of service life. Electrochemical O2 sensors require regular calibration and replacement, making them less suitable for oxygen deficiency monitoring.

Optional Remote Probe

Allows monitoring of locations away from the control unit. Comes standard with a 12 ft (3.6m) cable but can be extended by the customer up to 300 ft (91.4m).