LRP

The LRP is designed to prevent liquid slugs from ever reaching your analyzer during a routine pigging operation or upset conditions. The LRP contains a unique membrane and stainless steel disk combination that block liquids and particulates from passing, allowing only gasses to reach your Analyzer. When liquid slugs occur the LRP automatically shuts off gas until it passes. Once the liquid slug clears, liquid drains back into the pipeline and the LRP resumes gas flow to the Analyzer.

The LRP is available with a direct coupled NeSSI-compliant regulator. When the pipeline pressure exceeds the inlet pressure rating of the Analyzer, the regulator can be adjusted to bring the sample pressure down to 0-25 psig (0–1.7 bar). This option provides all the same benefits of the LRP in higher pressure applications.

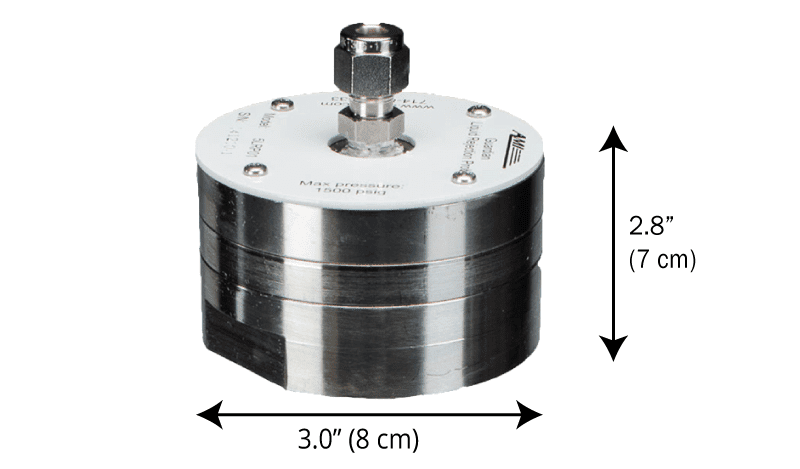

Technical Specifications

| Maximum Pressure | Connections | Maximum Flow Rate |

| 1500 psig (103 bar) | Inlet port: ½” FPT Output port(s): ¼” compression fitting | 5 SCFH |

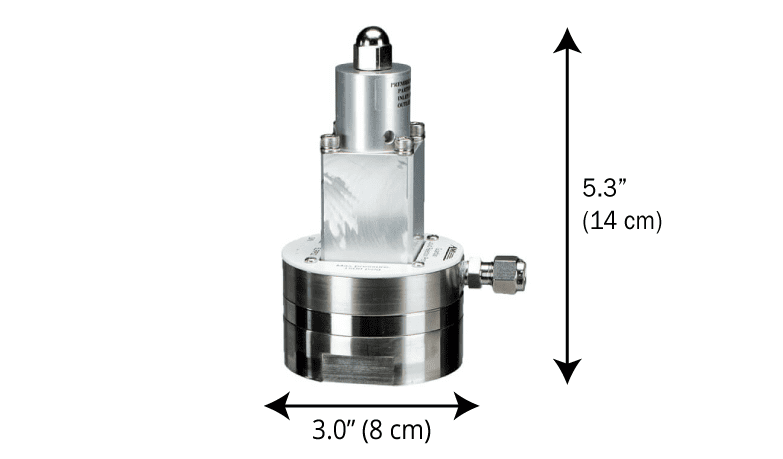

Technical Specifications (With Regulator)

| Maximum Pressure | Connections | Maximum Flow Rate |

| 0 - 25 psig (0 - 1.7 bar) outlet pressure 1500 psig (103 bar) maximum inlet pressure | Inlet port: ½” FPT Output port(s): ¼” compression fitting | 5 SCFH |

LRP Downloads

- LRP Data SheetAccessories-Data-Sheet.pdf (447 KB)

- LRP Operator ManualLRP-Manual.pdf (509 KB)