As of March 2022, the Russian ministry has recommended halting fertilizer exports to countries it deems ‘unfriendly’. These exports include potash, phosphate, and nitrogen-abundant fertilizer products. All these play vital roles in soil nutrition and farming. This decision has already sent fertilizer prices to record highs on the global market. In fact, prices are now 40% higher now than they were one month ago. With Russia representing 15% of the world’s supply, farming operations will undoubtedly incur higher costs and become impacted during this year’s harvest. Alternative sources of fertilizer production must now come ‘on-line’ to ease the supply shortage.

How fertilizer is produced

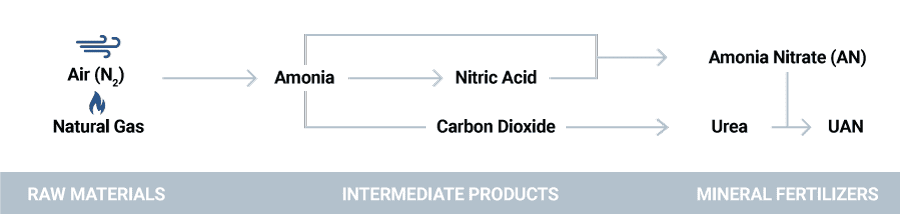

Understanding how fertilizer is produced is critical to solving shortages. In the simplest model, the process can be broken into 3 stages: raw materials, intermediate products, and, finally, mineral fertilizers. The two indispensable ingredients in fertilizer production are nitrogen (N2) and hydrogen (H2). Nitrogen gas is the largest component of the air we breathe, making it plentiful and relatively easy to secure. Nitrogen serves as crop nutrient and promotes plant quality and growth. For fertilizer use, nitrogen must be combined with hydrogen to a produce the intermediary product, ammonia. Ammonia contains a molecular structure that binds nitrogen which is ultimately used to create ammonium nitrate (NH4NO3). As a compound, ammonium nitrate is highly soluble in water and can be added directly to create commercially viable high-nitrogen content fertilizer.

The role of natural gas in fertilizer production

Natural gas is vital in the production of fertilizer. Natural gas has historically been the best source of hydrogen due to its low cost of acquisition, ultimately making it crucial for food production. Increasing the supply of fertilizer requires boosting the production of ammonia. This means there must be a readily supply of available natural gas - which happens to be in short supply right now.

In today’s market, the cost of natural gas has dramatically increased due to a variety of market and geopolitical reasons. This leaves fertilizer producers with no choice but to pay higher prices, assuming a reliable supply of the natural gas is available for purchase. This, in turn, is driving up the cost of fertilizers and, ultimately, food prices.

With no signs of natural gas demand decreasing, higher prices for the commodity are expected to stay. In turn, higher food costs are projected for stores and restaurants. The most effective and direct solution to deal with this is to increase natural gas production. In North America, this involves more investment in natural gas production and construction of the pipelines to move the gas to its destinations. Moving gas through pipelines is by far the safest and most economical method to transport the product from the producing areas to the refiners, terminals and, ultimately, fertilizer producers. In contrast, alternative options require higher transit costs, longer delivery times, and, in some cases, further processing of the gas into a liquid state.

AMI Gas Analyzers help keep pipelines flowing gas

For natural gas to continue flowing uninterrupted through pipelines, there must be stringent control over contaminates like oxygen, hydrogen sulfide and moisture in the gas stream. These contaminates can combine and cause damage and corrosion to the pipeline. To guard and prevent pipeline damage, pipeline operators have strict limits on these contaminants and will stop the flow of gas if any of these exceed the allowable levels.

Gas pipeline companies depend on AMI’s Oxygen, H2S and Moisture Analyzers to detect even the slightest levels of these contaminants. These Analyzers are designed with a sensitivity range in the parts per million (PPM). AMI’s units are routinely installed on major pipeline routes throughout the country in the largest oil and gas basins, from upstream points to midstream interconnections and, finally, downstream connections.

Whether it is a new pipeline installation, a new connection point to the pipeline, or just upgrading the monitoring performance on an existing pipeline, AMI’s Gas Analyzers deliver accurate, dependable and reliable measurements. This is the critical role AMI has played for over 20 years and looks forward to continuing as we help preserve the flow of natural gas. AMI’s dedication to this task will play a small but important role in keeping food prices under control.