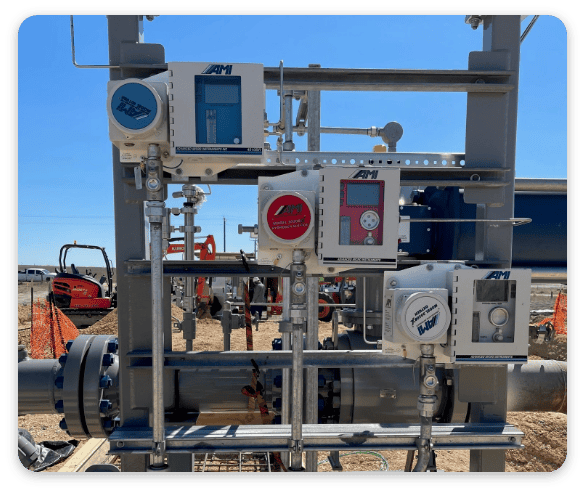

At extraction AMI oxygen analyzers are present to find issues early. Finding O2 ingress issues early will simplify oxygen removal down stream and protect the gathering system from corrosion.

AMI Gas Analyzers: Elevating Quality, Safety, and Efficiency Across the Natural Gas Value Chain

The natural gas industry is a cornerstone of modern energy production, powering homes, businesses, and industrial processes worldwide. However, ensuring the quality, safety, and efficiency of natural gas requires precise monitoring and analysis. We are AMI (Advanced Micro Instruments), a leader in gas analyzer technology, offering state-of-the-art solutions tailored to the unique demands of the natural gas sector. In this comprehensive guide, we’ll explore the critical role of gas analyzers in the natural gas industry, delve into AMI’s innovative offerings, and explain why their analyzers are the gold standard for pipeline operators, processors, and engineers.

Why Gas Analyzers Are Essential in the Natural Gas Industry

Natural gas, primarily composed of methane (CH4), is extracted from deep underground reserves formed over millions of years from organic materials subjected to intense heat and pressure. While methane is the star of the show, other valuable hydrocarbons such as ethane, propane, and butane will often be in the gas stream. There are also impurities like hydrogen sulfide (H2S), moisture (H2O), and carbon dioxide (CO2) that occur naturally in the gas stream. These bad actors along with oxygen (O2), that can enter the gas stream through leaks, can wreak havoc on pipelines, equipment, and end-use applications if not properly managed.

Gas analyzers are indispensable tools that monitor and measure these impurities to ensure the gas meets stringent quality standards for transportation, sale, and use. From extraction to custody transfer points, AMI’s analyzers play a vital role in:

- Preventing Corrosion: Trace levels of oxygen, H2S, and moisture can combine to form corrosive compounds that damage pipelines and infrastructure, costing the industry billions annually.

- Ensuring Safety: Harmful gases like H2S pose serious health risks to workers and communities if not detected and controlled.

- Meeting Tariff Standards: Pipeline operators and buyers enforce strict limits on contaminants to guarantee gas quality and contractual compliance.

- Optimizing Efficiency: Accurate gas composition data helps operators reduce transportation costs and maximize the heating value of the gas.

AMI’s advanced gas analyzers are designed to tackle these challenges head-on, offering unmatched precision, reliability, and durability in even the harshest environments.

AMI’s Role in the Natural Gas Industry

For over 25 years, AMI has been at the forefront of gas analysis technology, specializing in oxygen, H2S, and moisture analyzers that cater to the natural gas industry’s unique needs. Based in Costa Mesa, California, AMI combines patented technologies with rigorous quality control to deliver analyzers that outperform competitors while remaining cost-effective. AMI products are trusted by pipeline operators, gas processors, and Fortune 500 companies alike, making AMI a household name in the industry.

Key Applications of AMI Gas Analyzers

AMI analyzers are deployed at every stage of the natural gas value chain:

AMI’s Flagship Gas Analyzers for Natural Gas

AMI offers a suite of analyzers engineered specifically for the natural gas industry. Below are some standout models, each packed with innovative features to address the sector’s toughest challenges. All are designed to work in hazardous environments, meeting stringent approvals like ATEX and IECEX.

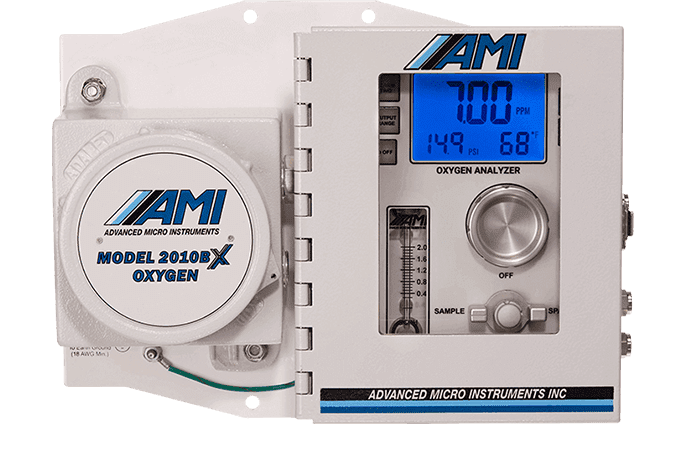

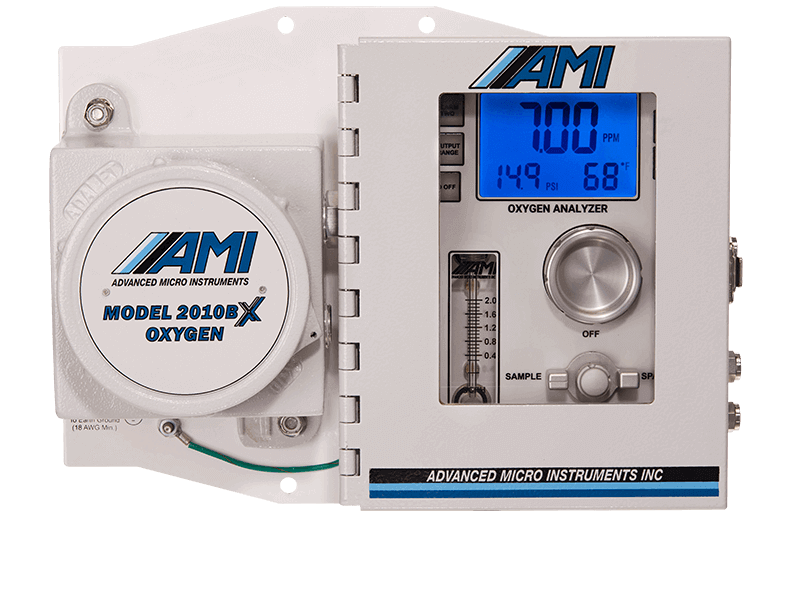

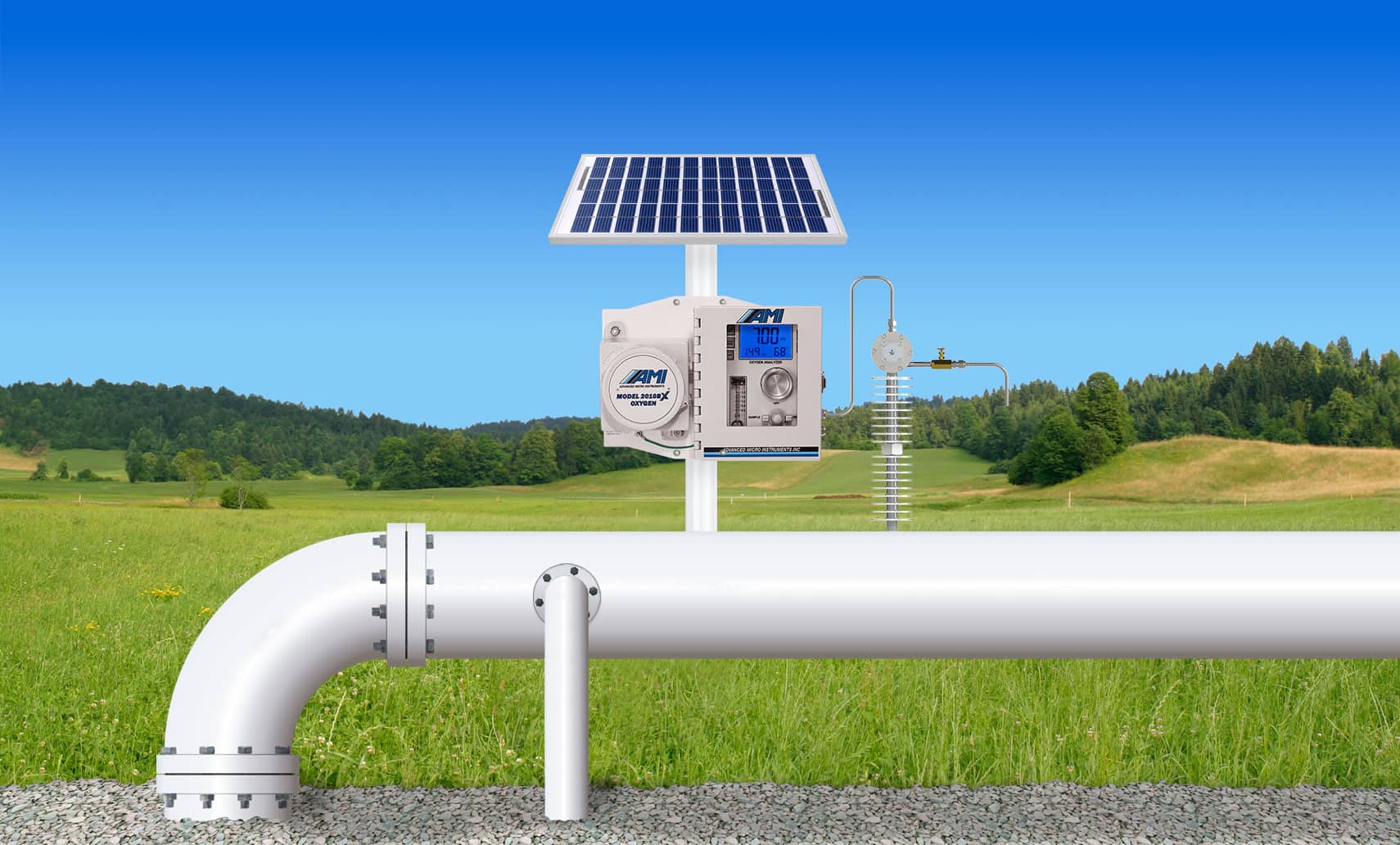

Trace Oxygen Analyzer MODEL 2010BX

- Purpose: Measures trace oxygen levels (ppm) in natural gas.

- Key Features:

- Proprietary Eliminator Cell Block for leak-free performance and rapid response times.

- Advanced electrochemical sensors with resistance to H2S up to 500 ppm, eliminating the need for scrubbers.

- Integrated heater to protect sensors in freezing conditions.

- Applications: Pipeline leak detection, custody transfer verification, and corrosion prevention.

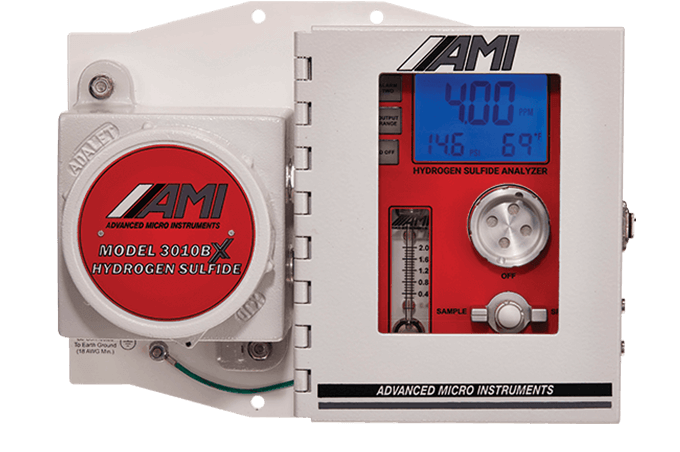

Trace H2S AnalyzerMODEL 3010BX

- Purpose: Detects trace hydrogen sulfide levels in natural gas streams.

- Key Features:

- High sensitivity down to 0.1 ppm, ideal for early detection of corrosive H2S.

- Rugged Class I, Div 1 certification for hazardous environments.

- Fast, reliable measurements with minimal maintenance.

- Applications: Sulfur removal monitoring, worker safety, and tariff compliance.

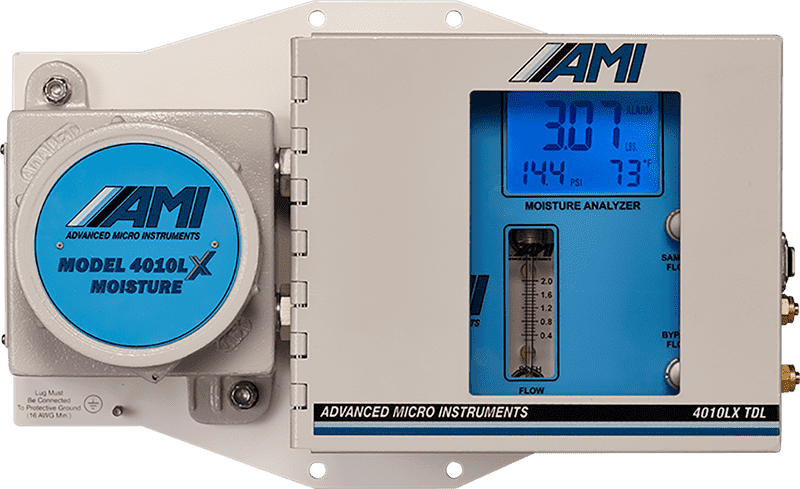

Moisture AnalyzerMODEL 4010LX TDL

- Purpose: Analyzes trace moisture content in natural gas.

- Key Features:

- Tunable Diode Laser (TDL) technology for fast, accurate readings unaffected by gas contaminants.

- Compact, solar-power-compatible design for remote field use.

- Remote peak realignment software to maintain accuracy without downtime.

- Applications: Dehydration process control, pipeline protection, and custody transfer.

Portable Trace Oxygen AnalyzerMODEL 1000BX

- Purpose: Portable spot-checking of oxygen levels.

- Key Features:

- Lightweight, Class I, Div 1-rated design for hazardous areas.

- Quick, precise measurements to track down oxygen ingress sources.

- Data logging capabilities to record up to 15 days of readings from one or multiple sites.

- Applications: Field troubleshooting, leak detection, and dispute resolution.

Portable Trace H2S AnalyzerMODEL 3000BX

- Purpose: Portable spot-checking of H2S levels.

- Key Features:

- Lightweight, Class I, Div 1-rated design for hazardous areas.

- Quick, precise measurements as an alternate to stain tubes.

- Data logging capabilities to record up to 15 days of readings from one or multiple sites.

- Applications: Field troubleshooting and dispute resolution.

The Technology Behind AMI’s Success

What sets AMI apart from competitors? Our proprietary innovations ensure superior performance and reliability:

Eliminator Cell Block

A machined metal block integrates all sample-handling components (flow meter, valves, etc.) into a leak-proof system, delivering up to 400% faster response times than traditional designs.

Proprietary Sensor Technology

AMI’s electrochemical oxygen sensors offer rapid response, H2S resistance, and long-term stability, tested across extreme conditions to meet strict quality standards.

Command Center Software Platform

This user-friendly interface provides advanced features like programmable alarms, data logging, and remote diagnostics at no extra cost.

TDL Moisture Measurement

The MODEL 4010BX laser-based technology ensures precise moisture readings, even in contaminated gas streams, outperforming older methods like chilled mirrors.

These innovations make AMI analyzers not only more effective but also easier to use and maintain, saving operators time and money.

Benefits of Choosing AMI Gas Analyzers

When you invest in AMI analyzers, you’re not just buying equipment—you’re gaining a competitive edge. Here’s why:

Accuracy

Detect trace contaminants down to parts-per-million (ppm) levels with confidence.

Durability

Built to withstand harsh outdoor conditions, from freezing winters to scorching summers.

Cost Savings

Priced 20-60% lower than competitors, with minimal maintenance and no need for additional components.

Performance

Eliminator Cell Block design eliminates leaks and provides fast measurement response time. Compact design minimizes weight. Low power consumption allows powering with a solar panel.

Safety

Protect workers and infrastructure with real-time monitoring and reliable alarms. Certified for operation in hazardous areas.

Compliance

Ensure gas meets pipeline tariffs and regulatory standards, avoiding penalties or shut-ins.

Challenges in Natural Gas Analysis and AMI’s Solutions

The natural gas industry faces several unique challenges when it comes to gas analysis:

1. Oxygen Ingress

- Challenge: Even sub-10 ppm oxygen levels indicate leaks, posing corrosion risks.

- AMI Solution: The MODEL 2010BX and 1000BX detect trace oxygen with pinpoint accuracy, acting as virtual “leak detectors.”

2. Moisture Control

- Challenge: Excess moisture increases corrosion and transportation costs.

- AMI Solution: The MODEL 4010LX provides continuous, reliable moisture readings to optimize dehydration processes.

3. H2S Detection

- Challenge: Low H2S levels can still cause corrosion and health hazards.

- AMI Solution: The MODEL 3010BX offers unmatched sensitivity and durability for H2S monitoring.

4. Harsh Environments

- Challenge: Analyzers must operate in remote, extreme conditions without failing.

- AMI Solution: Rugged oxygen, moisture, and H2S analyzers certified for Class I, Div 1 with integrated heaters (oxygen and H2S only) and solar-powered options to operate anywhere.

How AMI Supports the Natural Gas Industry Beyond Analyzers

AMI doesn’t stop at manufacturing top-tier analyzers. They also provide:

- Accessories: The Demister and Analyzer Guardian protect analyzers from hot gases and liquid slugs, extending their lifespan. The Extreme Weather Enclosure provides additional weather protection, expanding the temperature range the analyzers can operate.

- Command Center Software: Powerful software platform developed by AMI that gives users access to advanced functions of our analyzers.

- Customer Support: With a dedicated team in California, AMI offers expert guidance and fast service. Additionally we partner with a global network of distributors to support our products locally.

The Future of Gas Analysis with AMI

As the natural gas industry evolves, so does AMI. Their commitment to innovation ensures they stay ahead of emerging trends, such as:

- Renewable Natural Gas (RNG): AMI analyzers are already used to monitor biogas upgrading, ensuring RNG meets pipeline standards.

- Digital Integration: The Command Center platform paves the way for smart, IoT-enabled gas analysis.

- Sustainability: By preventing leaks and optimizing gas quality, AMI supports greener, more efficient operations.

Why AMI Is the Best Choice for Natural Gas Analyzers

In the high-stakes world of natural gas, precision and reliability are non-negotiable. AMI’s gas analyzers—backed by decades of expertise, patented technology, and a customer-first approach—deliver exactly that. Whether you’re safeguarding pipelines, ensuring tariff compliance, or troubleshooting in the field, AMI has the tools you need to succeed.

Natural Gas Downloads

Getting Started

Ready to elevate your natural gas operations? Visit www.amio2.com to explore AMI’s full range of analyzers or contact their team at 714-848-5533 for a personalized quote. With AMI, you’re not just measuring gas—you’re mastering it.